Metal fabrication processes are prone to defects, many of which are difficult to detect with the naked eye and unsuitable for manual inspection. Manual inspection is also time-consuming and often yields inconsistent results. In contrast, AI-based visual inspection offers not only economic benefits but also enhanced quality and consistency.

PEKAT VISION has been successfully deployed in various stages of metal fabrication, from input material inspection to assembly and packaging verification. Its reliable visual inspection, powered by advanced deep-learning algorithms and neural networks, easily identifies anomalies and detects and classifies defects. These defects include cracks, scratches, sand inclusions, blowholes, corrosion defects, stains, and many other imperfections.

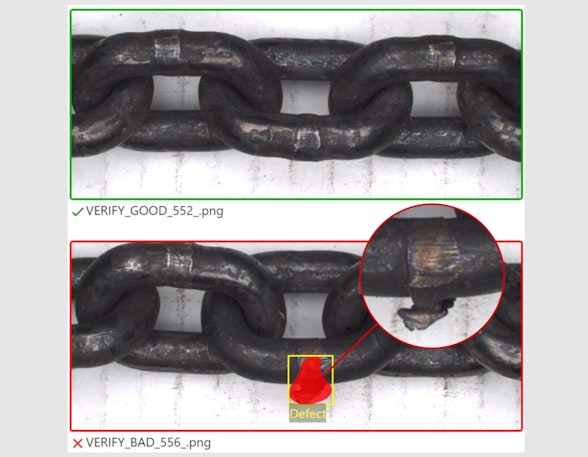

Chain Anomaly Detection

The PEKAT VISION Anomaly Detector module is ideal for detecting defects on metal chains. Due to the variety of potential defects, the Anomaly Detector, which is trained only on defect-free images, was chosen for the inspection shown above.

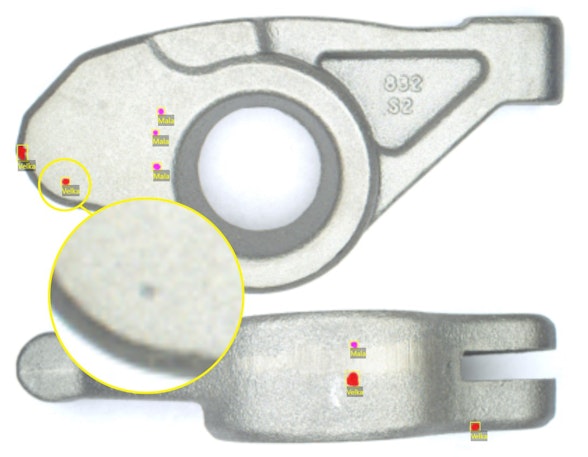

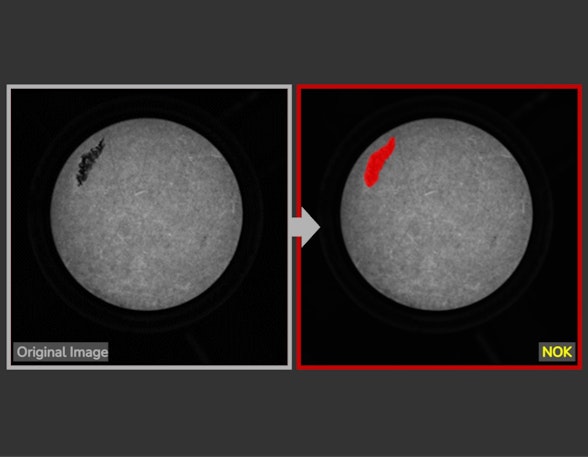

Surface Defect Detection of Iron Casting

In the image above, the Surface Detection module identifies anticipated defects in iron casting. These defects mainly consist of dents of various sizes, which are easily detected and classified by PEKAT VISION Detector and Classifier modules.

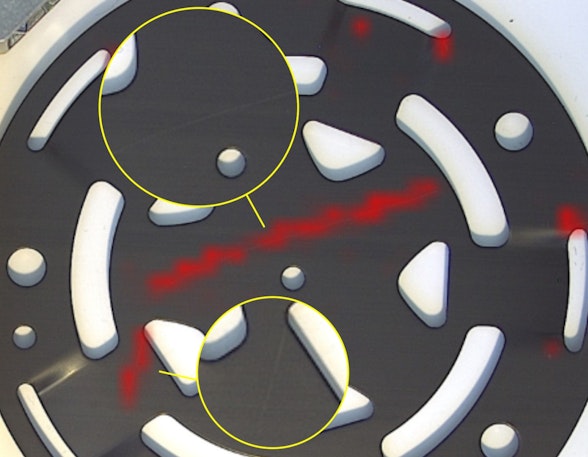

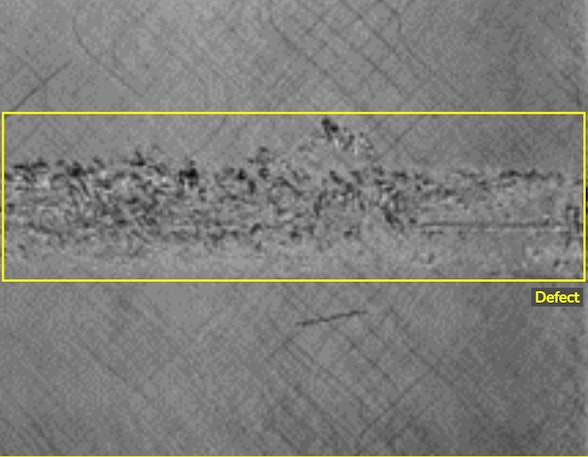

Surface Scratches Identification

Both the Anomaly Detector and Surface Detector modules can identify surface defects such as scratches, dents, and paint defects. The choice between these modules depends on various factors, including lighting conditions, material structure, and product variety.

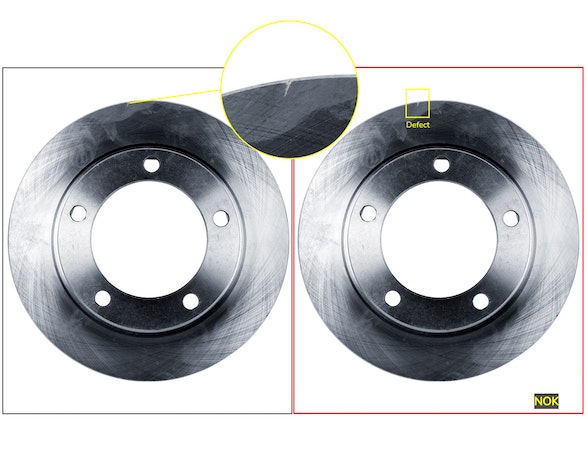

Brake Disc Inspection

Safety-critical visual inspection with PEKAT VISION detects cracks and other defects in brake discs that could lead to increased noise levels, wear and tear, or even safety hazards. The PEKAT VISION Detector module was used for this inspection.

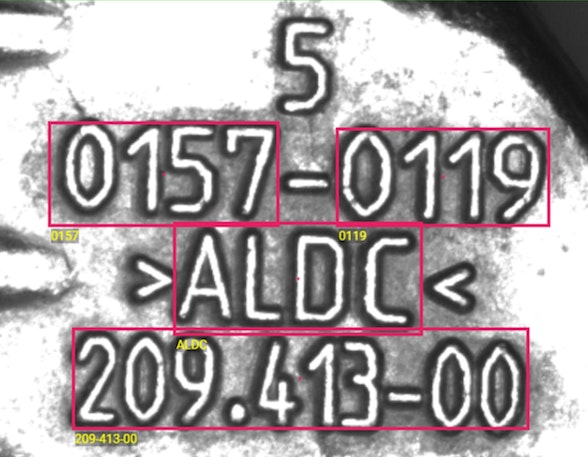

Optical Character Recognition

PEKAT VISION’s OCR module extracts various flat or embossed characters, symbols, and strings of text from a variety of surfaces. This includes stamped part numbers, serial numbers, batch information, and more, even when they are barely visible to the human eye.

Inspection of Bearing Elements

The Surface Detector module is also well-suited for inspecting bearing elements, as shown in the image above. Early identification of defective parts reduces the likelihood of malfunction in assembled units, minimizing scrap and costly rework.

Detection of Structural Defects in Metal

PEKAT VISION detects material defects in machined metal parts before further processing, ensuring higher quality and reducing the chances of costly errors.

Why PEKAT VISION

And more! Ask for a free feasibility study for your specific case. Our software is highly versatile and can be customized to suit nearly any intended application.