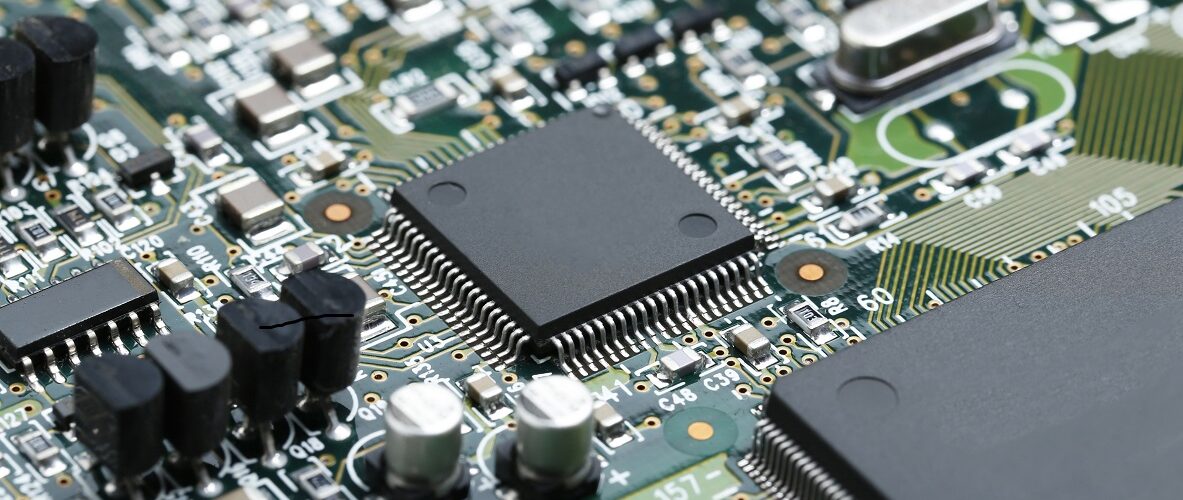

AI visual inspection has become increasingly popular in the electronics industry as a crucial component of quality control. The ability of AI to detect defects with high accuracy and speed makes it an attractive solution for manufacturers aiming to enhance product quality and reduce the costs associated with manual inspection.

PEKAT VISION offers deep-learning-based visual inspection for electronic components and printed circuit boards (PCBs). Our technology identifies defects such as missing components, misaligned parts, soldering issues, and other manufacturing errors. The benefits of using PEKAT VISION include increased accuracy, speed, reduced costs, and improved consistency. Additionally, it can detect defects that are difficult or impossible for human inspectors to identify.

PEKAT VISION is easy to use, set up, and maintain. Explore some of our use cases below or request a free demo to experience the benefits of our software firsthand.

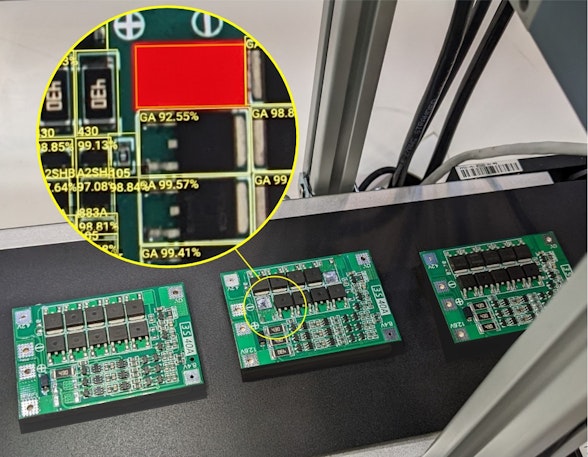

PCB – Components Presence/ Absence

The Detector and Classifier modules are ideal for verifying the presence and condition (OK/NOK) of individual components on PCB boards. In the image above, over fifty individual components are inspected for accuracy and quality.

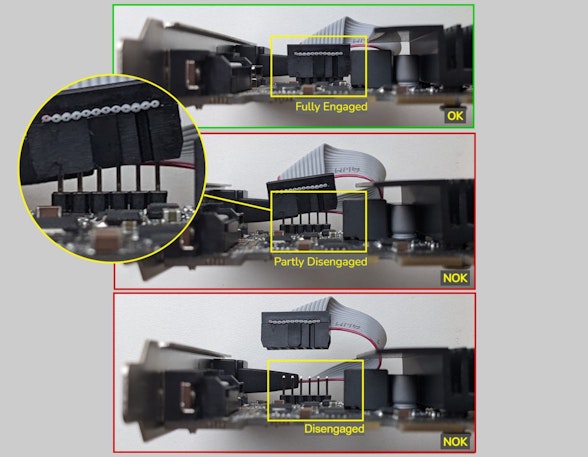

Pin Connector – Assembly Verification

Proper engagement of female and male connectors on PCB component is verified. Since the PCB components were in a static position, the Classifier module was sufficient for this task.

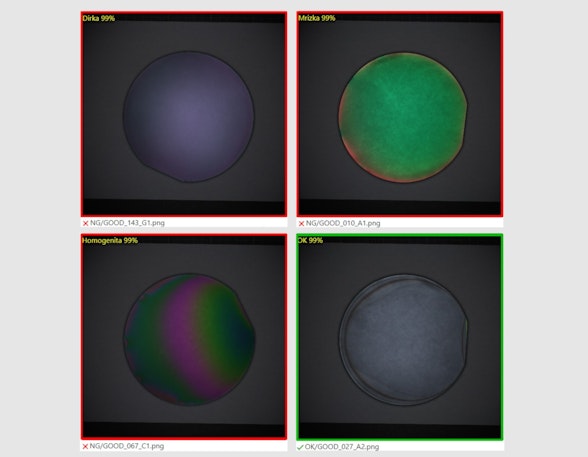

Wafer Classification

The Object Detector and Classifier modules of PEKAT VISION are frequently used for wafer classification.

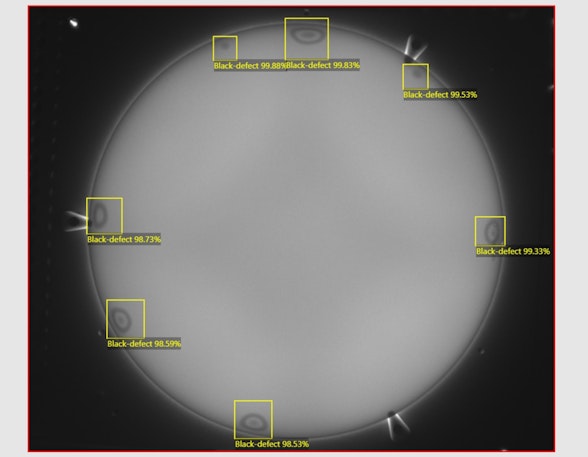

Wafer Internal Defect Inspection

Internal defects on a wafer are identified using PEKAT VISION’s Object Detector and Classifier modules, as shown in the image above.

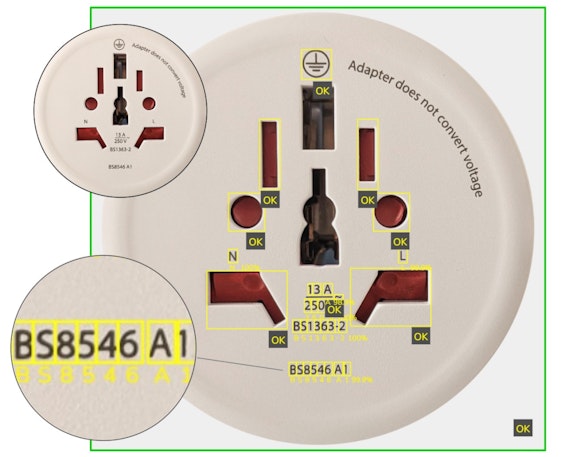

OCR and Safety Features Verification

In the image above, the Detector and OCR modules are used together to verify that all safety features of the socket adapter, including required labeling and protective plastic covers, are in place.

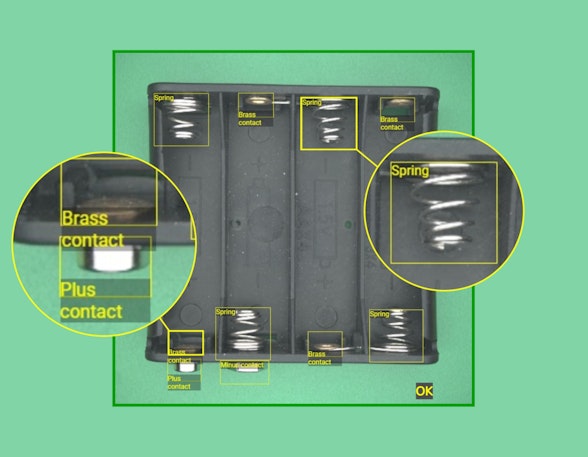

Component Presence/ Absence Inspection

This example demonstrates component presence inspection. All components, including the brass contact, spring, and minus and plus contacts, are identified and confirmed.

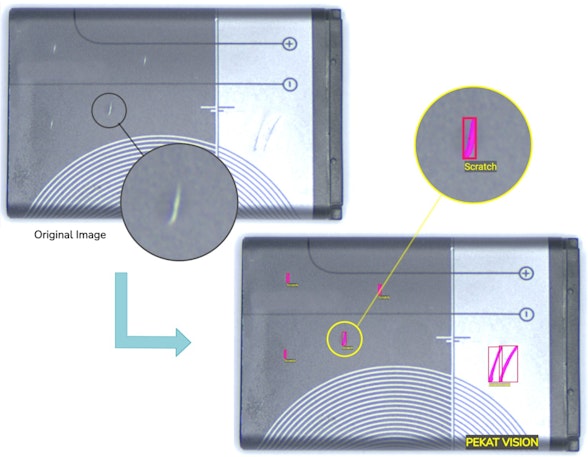

Battery Surface Inspection

The PEKAT VISION Surface Detector module detects and classifies various types of defects that may occur during the production process of EV or other batteries, including scratches, dents, and glue residues.

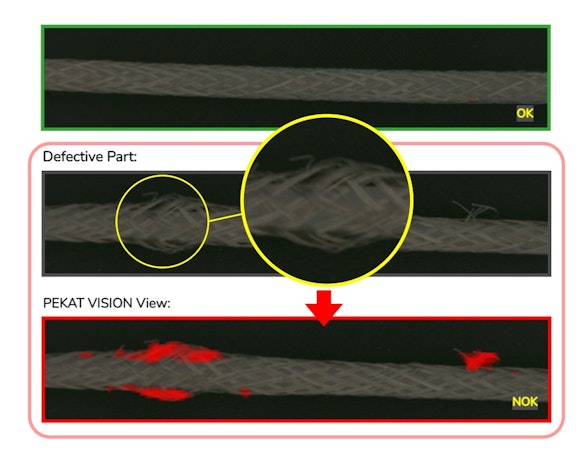

Braided Cable – Anomaly Inspection

The integrity of the braided shielding is inspected using the Anomaly Detector module. Defects are easily identified and highlighted with a heat map. The module is trained exclusively on defect-free images.

Why PEKAT VISION

And more! Ask for a free feasibility study for your specific case. Our software is highly versatile and can be customized to suit nearly any intended application.