Due to the inconsistent texture of wood, each piece is unique, making quality control a challenging task. PEKAT VISION’s deep learning neural network overcomes these challenges by learning to understand the texture from a set of images, helping to determine whether the required quality is achieved.

It grades wood based on quality and determines the suitability of each piece for specific applications, greatly increasing speed and consistency while reducing inspection costs.

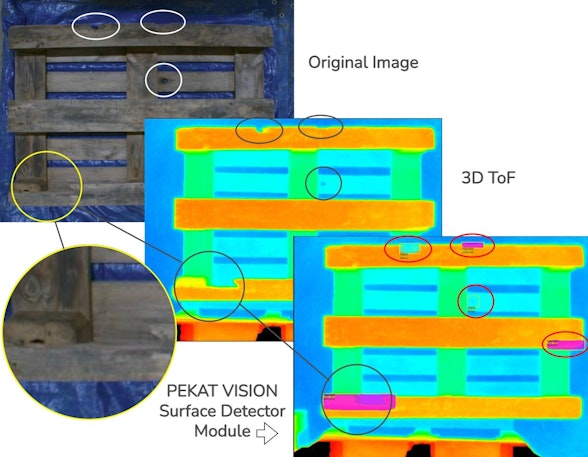

Inspection of Wooden Palletes for Recycling

Using the Surface Detection module, PEKAT VISION helps companies identify defects on pallets destined for recycling. 3D imaging technology aids in identifying even hard-to-see defects, ensuring thorough inspection.

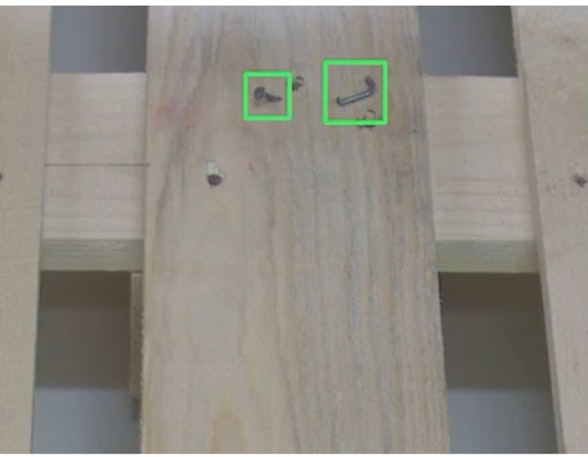

Inspection of Wooden Palletes – Nails

PEKAT VISION detects insufficiently hammered nails that protrude from the pallet, which can cause complications during transport, damage the transported goods, or even lead to injury.

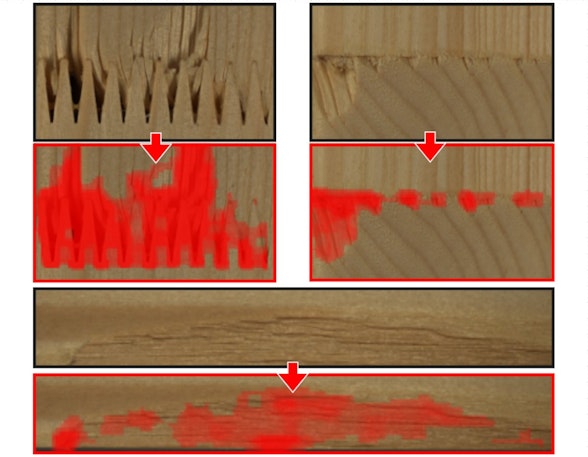

Anomaly Detection of Wooden Planks

The Anomaly Detection module is ideal for detecting previously unseen defects or defects where the shape and size are difficult to anticipate, ensuring comprehensive quality control.

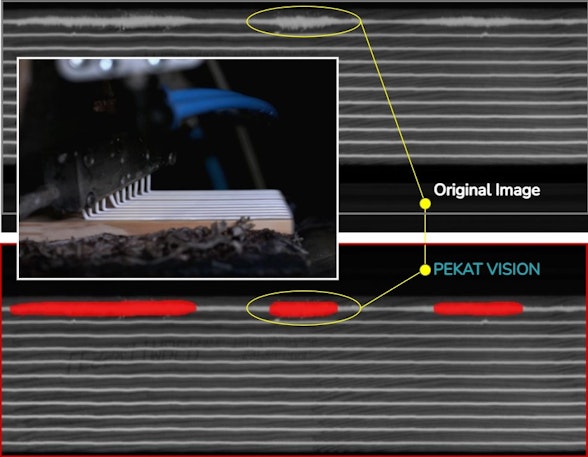

Glue Irregularities Detection

The Surface Detection module also identifies irregularities in glue or other adhesive layers, ensuring proper application and adhesion.

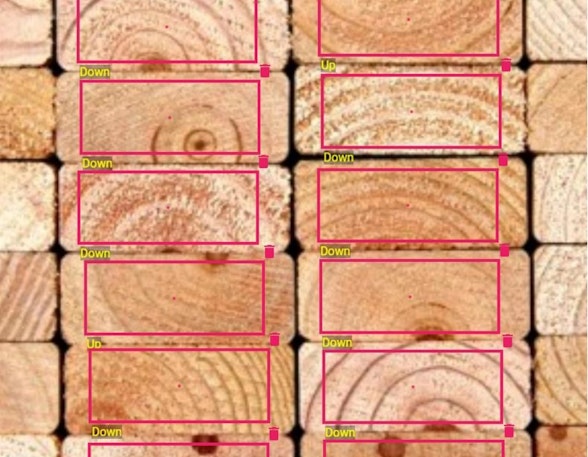

Annual Rings Orientation

The Object Detector module of PEKAT VISION is used to identify the orientation of annual rings on wooden planks, crucial for certain applications.

Wood Knots Detection & Classification

Wood knots adversely affect wood strength. For some applications, it is necessary to determine the type of knots present, such as encased knots, ingrown knots, decayed knots, spiked knots, etc. PEKAT VISION classifies these knots to ensure the wood meets the required standards.

Why PEKAT VISION

And more! Ask for a free feasibility study for your specific case. Our software is highly versatile and can be customized to suit nearly any intended application.