A renowned Italian pasta manufacturer recently approached us with a unique request: they needed a solution to inspect the length of each piece of one of their premium pasta products. While we’ve provided various quality inspection solutions for pasta manufacturing before, measuring the length of pasta was a new challenge for us.

The Challenges of Pasta Inspection

PEKAT VISION comes equipped with a built-in Measure module, but typically, this module works best when the objects to be measured are stationary in the images. The challenge with pasta is that it’s randomly scattered across the conveyor belt, making it difficult to measure consistently. Additionally, the manufacturer required a solution capable of handling their high production speed, meaning the system had to process images quickly without sacrificing accuracy.

A Simple, Flexible Solution

One of PEKAT VISION’s key advantages is its flexibility. Beyond its core deep learning modules, it also offers a versatile Code module. By combining the deep-learning Detector module with a few lines of custom code written by our expert feasibility team, we were able to develop a quick and efficient solution tailored to this specific task.

How It Works

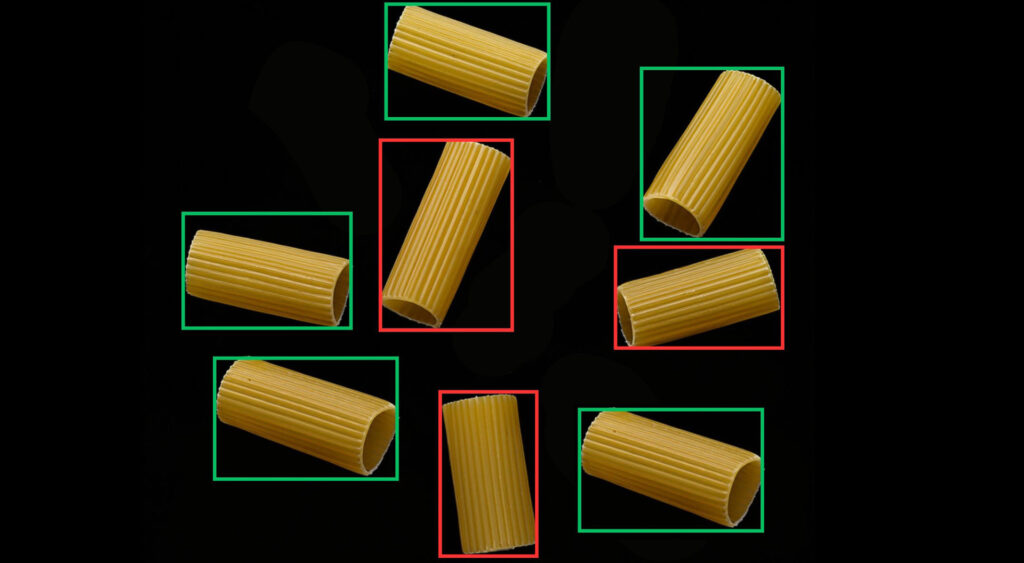

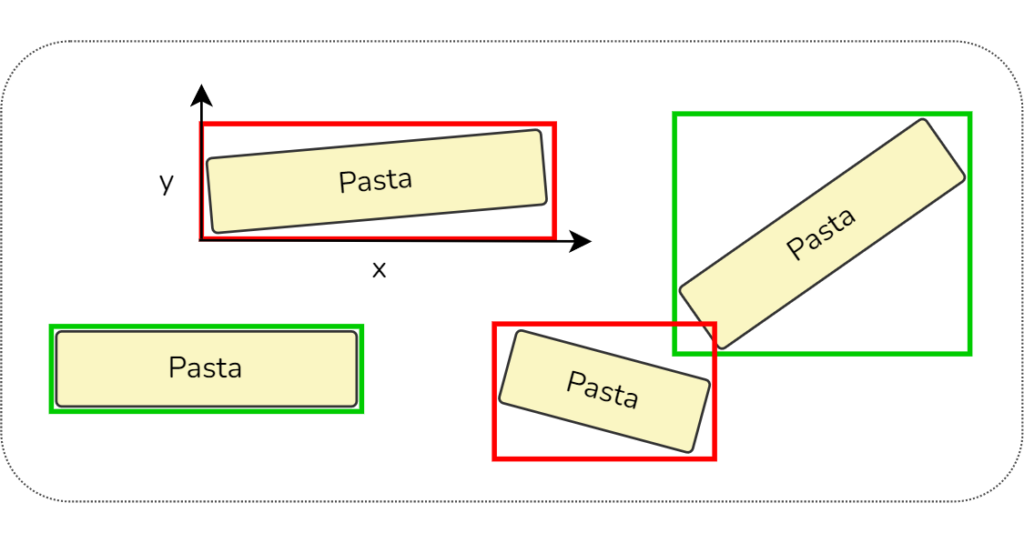

The customer needed a straightforward and fast solution, and that’s exactly what we delivered. In the first step, we used PEKAT VISION’s Detector module to identify and mark each piece of pasta in the images, drawing a bounding box (rectangle) around them. Next, the length of each bounding box, measured in pixels, was compared to the required specifications. Simple, right? Not quite.

Fine-Tuning for Accuracy

The drawn rectangles followed the ‘x’ and ‘y’ axes, while the pasta was randomly oriented on the conveyor belt. This meant that the actual length of each pasta piece could be skewed. To correct this, we applied an aspect ratio coefficient to account for the varying orientations of the pasta pieces, ensuring precise length measurements regardless of their position or tilt on the belt.

Handling Incomplete Pasta Pieces

We’ve encountered similar challenges in previous use cases, like when detecting defects on continuous materials where issues occurred at the boundary between consecutive images. There, we solved the problem by cropping the bottom 20% of each image and merging it with the next.

For this pasta inspection, we implemented a slightly different approach. We created a margin around the borders of each image and only considered whole pieces of pasta that lay outside this margin. Overlapping images with these margins ensured that no pasta piece went uninspected.

Delivering the Perfect Solution

The result was a fast, efficient, and highly accurate solution that exceeded the customer’s expectations. By leveraging PEKAT VISION’s flexibility and adaptability, we provided a system capable of meeting both the technical and production demands of the pasta manufacturer, ensuring consistent quality and accuracy at high speed.

Discover other food and beverage applications of PEKAT VISION, and read about how NIR imaging enhances food quality inspection or how the Surface Detection module ensures the highest quality of salmon meat.