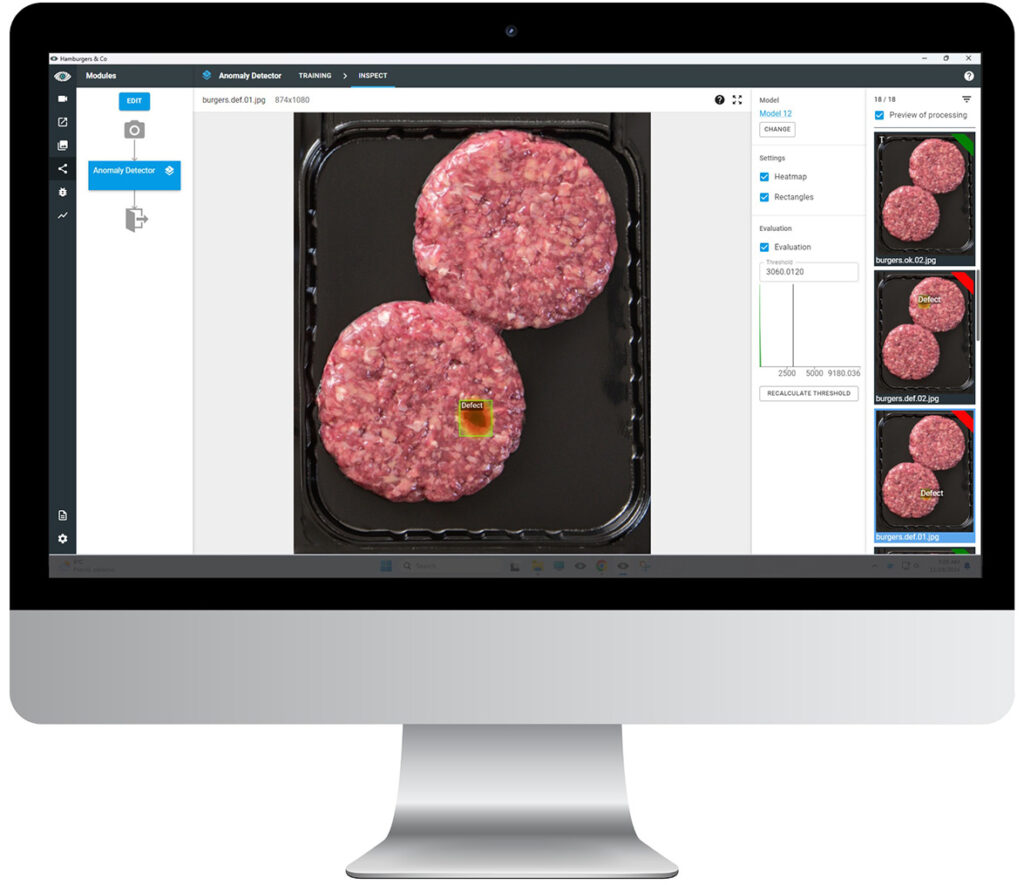

In recent weeks, we’ve explored complex use cases requiring multiple PEKAT VISION modules and customization through the Code module, which allows scripts to be easily integrated into inspections. However, many applications can be addressed with just one module. This use case demonstrates how the Anomaly Detector module effectively handles final packaging inspection in meat production, focusing on detecting contaminants in packaging with hamburgers, cevapcici, and hotdogs before sealing.

Detecting foreign objects in this context presents a unique challenge due to the indefinite variety of possible contaminants. The Anomaly Detector was the ideal choice because it is trained only on defect-free images, learning how an “OK” product should look and flagging any deviations. This unsupervised approach makes it particularly versatile and efficient.

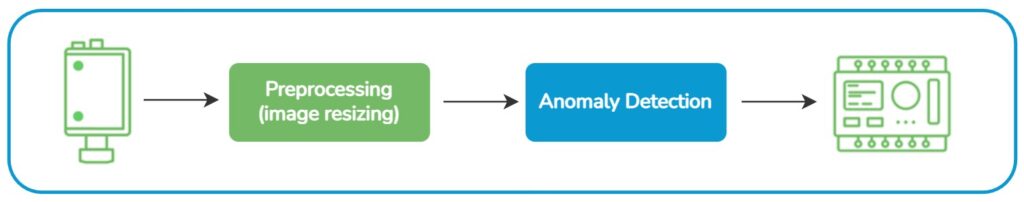

To train the module, we used just over 20 images capturing the natural variations of the products and their positions within the packaging. Because of the large image file sizes due to our camera choice, we resized the images to optimize processing speed. The result was remarkable: the Anomaly Detector processed each package in under 100 milliseconds, easily meeting the requirement of inspecting 2–3 packages per second, and successfully identified every contaminant it was tested on.

While the Anomaly Detector excels in speed, ease of training, and its ability to detect previously unseen defects, it does not classify the contaminants or defects. For applications requiring classification, PEKAT VISION offers the Detector & Classifier and Surface Detection modules. For example, the Surface Detection module was used in inspecting salmon meat, while the Detector module excelled in inspecting puffed rice cookies for defects, both modules enabling classification of defects.

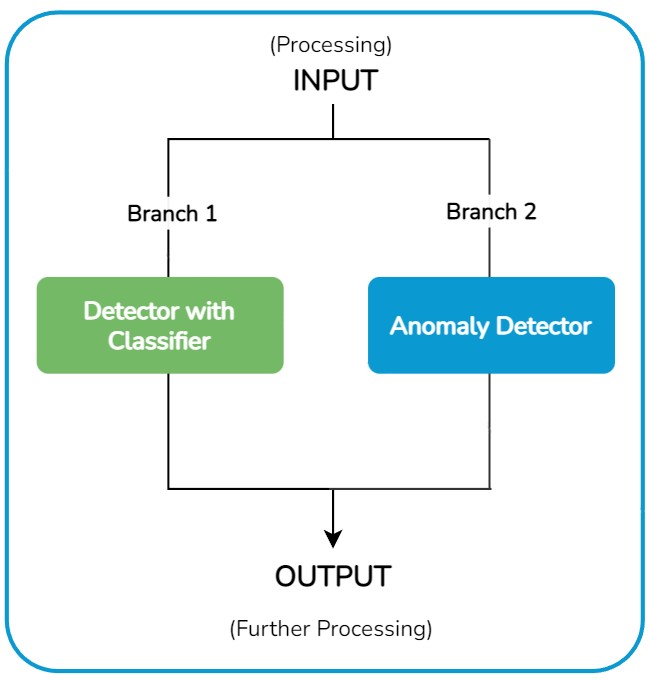

Sometimes, combining modules delivers the best results, ensuring that known contaminants and defects are classified while also identifying never before seen defects. For instance, in a cleanliness inspection of plastic boxes, the Detector & Classifier modules identified known defects in one branch, while the Anomaly Detector flagged novel ones in another branch, all in just milliseconds.

If you’re unsure which module or combination suits your needs, we offer a free feasibility study. This allows us to assess your specific inspection challenges, determine the software’s suitability, and recommend the best solution. Send us your feasibility request or contact us directly to discuss how PEKAT VISION can help optimize your quality inspection process.