Deep-learning based visual inspection by PEKAT VISION plays a critical role in the construction industry by facilitating defect and anomaly detection across various building materials. From pavement blocks to bricks, tiles, flooring materials, glass, and marble, as well as their packaging, PEKAT VISION ensures rigorous quality control at every stage of production and distribution.

Its advanced algorithms analyze surface textures, patterns, and structural integrity, identifying imperfections such as cracks, chips, stains, or uneven finishes that can compromise aesthetics and durability.

Moreover, PEKAT VISION’s user-friendly interface simplifies setup, maintenance, and operation, making it an indispensable tool for enhancing product quality, minimizing rework, and optimizing manufacturing efficiency in the construction sector.

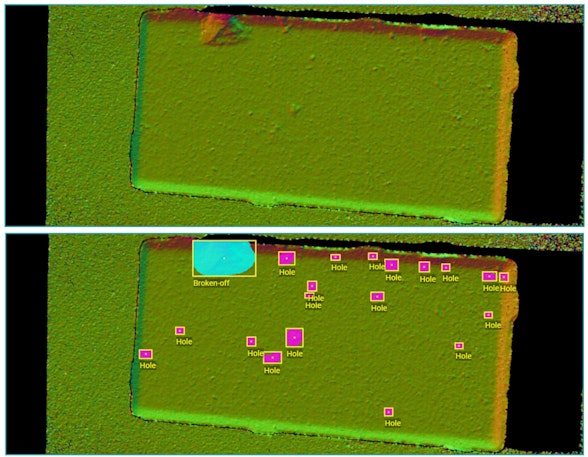

3D Paving Block Inspection

Paving blocks, like bricks and tiles, can be inspected using either 2D cameras or 3D scanners, as pictured above. The PEKAT VISION Surface Detector module detects several classes of defects in this process.

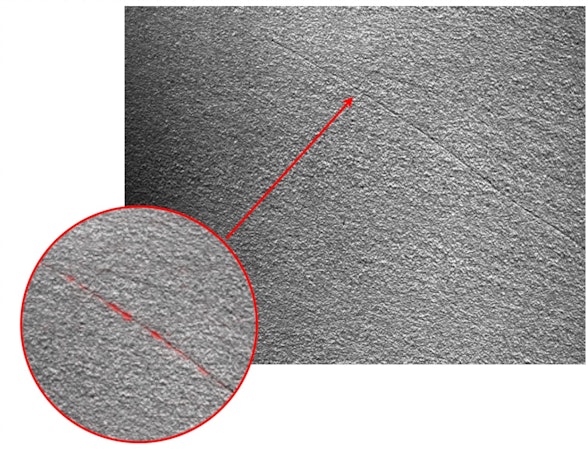

Surface Inspection of Cork Plates

Cork plates are inspected using line-scan cameras to detect surface defects such as scratches and imperfections. PEKAT VISION’s software analyzes these images, ensuring only flawless products reach customers.

Brick Defect Detection

Utilizing a 3D laser scanner, defects in bricks are accurately identified and analyzed using PEKAT VISION’s powerful image processing capabilities.

Why PEKAT VISION

And more! Ask for a free feasibility study for your specific case. Our software is highly versatile and can be customized to suit nearly any intended application.