PEKAT VISION’s visual inspection and quality assurance software, powered by proprietary deep-learning algorithms and neural networks, has become an essential tool in the pharma sector. It ensures product quality by verifying packaging and seal integrity, maintaining sterility, and ensuring appropriate labeling, all of which help in meeting regulatory compliance.

PEKAT VISION offers a comprehensive set of tools designed to tackle various challenges in pharmaceutical and cosmetics manufacturing. These include completeness verification, packaging integrity inspection, defect and contaminant detection, label reading and verification, and much more. Below are some recent examples showcasing PEKAT VISION’s capabilities.

Liquid Level Measurement

PEKAT VISION has recently been applied to measure the liquid level in antigen tests, addressing complaints during the COVID pandemic about insufficient or absent test liquids in ampoules. This technology also inspects the liquid content of vials, ampoules, and bottles, often complemented by packaging integrity and contaminant detection inspections. A backlight is frequently used for white or amber packaging.

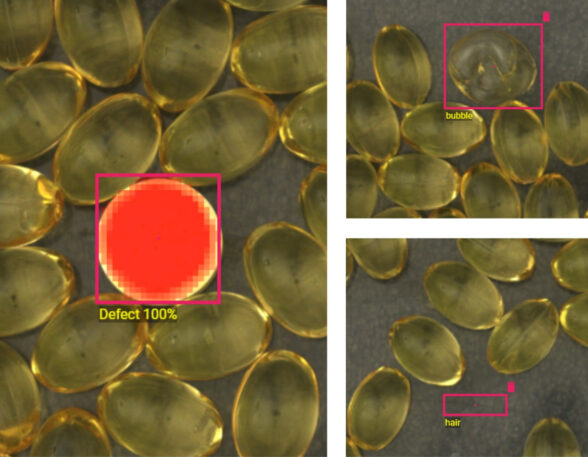

Foreign Object/ Contaminant Detection

PEKAT VISION’s Anomaly Detector and Object Detector are used to identify foreign objects in packaging or liquids. The Anomaly Detector is trained on OK images only and detects deviations, as seen in the left image above. The right two images illustrate the Object Detector module, which is trained to identify specific objects.

Hypodermic Needle Sharpness Inspection

Needle sharpness directly impacts the pain level during injections, a critical concern for needle manufacturers. PEKAT VISION’s Classifier module offers fast and reliable inspection to ensure optimal sharpness.

Pill Integrity Inspection

The Detector and Classifier modules verify that pills meet required specifications, including dimensions, shape, texture, and color, ensuring they are free of defects.

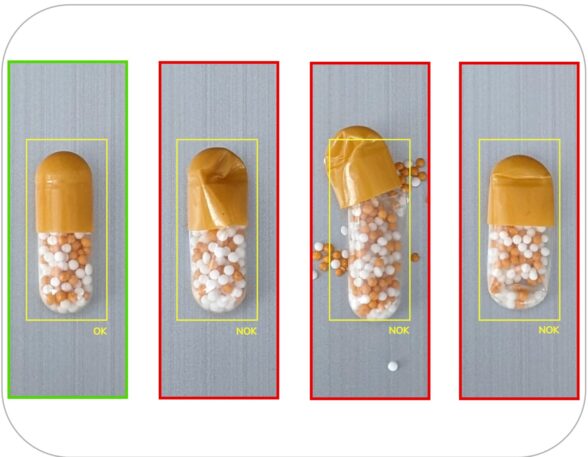

Packaging Inspection

PEKAT VISION’s Detector and Classifier modules ensure completeness verification, guaranteeing that only complete packages are distributed by the manufacturer.

Pill Blister Inspection

In the image above, PEKAT VISION’s Detector and Classifier modules inspect the integrity of pill blisters. Individual pockets are detected and classified as OK or NOK based on the state of the pill inside each pocket.

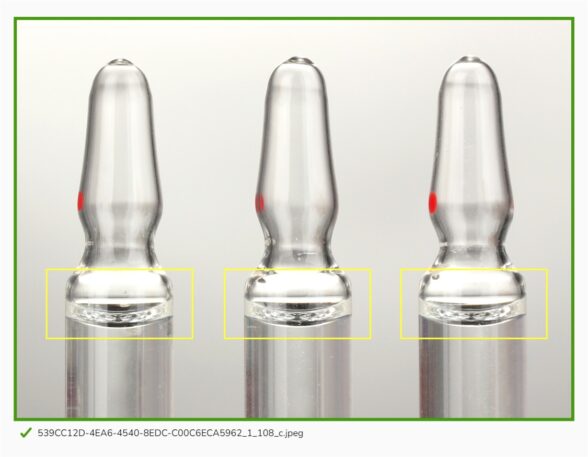

Vial Liquid Level Inspection

Vials are crucial for storing liquid medications, and the proper liquid level ensures accurate dosing. The image above shows PEKAT VISION’s Classifier module inspecting the liquid level in vials. Learn more in our blog.

Why PEKAT VISION

And more! Ask for a free feasibility study for your specific case. Our software is highly versatile and can be customized to suit nearly any intended application.