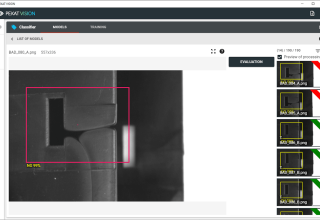

Automating PCB Inspection

April 16th 2025

Our example project demonstrates how multiple PEKAT VISION modules—Detector, Unifier, and Classifier—work together to inspect PCB components.

Read more

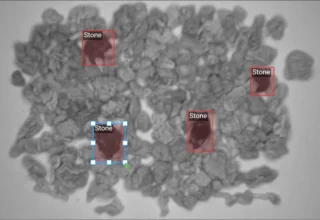

Detecting Food Contaminants with the Detector Module

April 3rd 2025

Take a closer look at how does the detector module work in food inspection. Now, you can try it yourself—or just read along.

Read more

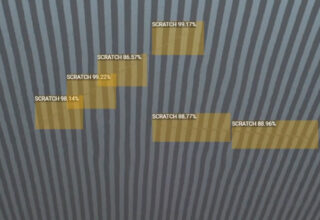

Defect Detection on Reflective Surfaces

February 21st 2025

Patterned illumination significantly enhances defect detection on glossy and reflective surfaces. Combined with PEKAT VISION's deep learning software, it provides a reliable, automated quality control solution for challenging inspection tasks.

Read more

PEKAT VISION RELEASE 3.18: What’s New?

January 17th 2025

The latest release of PEKAT VISION, version 3.18, brings exciting new features and improvements designed to enhance performance, usability, and flexibility for your quality inspection projects.

Read more

Ensuring Patient Safety with Reliable Catheter Packaging Inspection

January 9th 2025

Discover how PEKAT VISION detects incomplete or improperly sealed catheter packages to meet the highest quality standards.

Read more

Quality Inspection of Chocolate Boxes

December 20th 2024

With the festive season fast approaching, what better way to celebrate than with a Christmas-themed use case? This time, we explore quality inspection of Christmas chocolate boxes—specifically focusing on completeness inspection. In...

Read more

AI-Powered Safety Inspection for Railway Carriages

December 13th 2024

Deep learning for railway safety inspections? We recently tackled an unconventional use case—automating the inspection of locks and latches on slowly moving railway carriages!

Read more

Final Packaging Inspection in Meat Production

December 5th 2024

Explore how PEKAT VISION's Anomaly Detector streamlines packaging inspection in meat production, detecting foreign contaminants like foil or paper and ensuring the highest quality before sealing. Learn more about its speed, accuracy, and flexibility for food inspection.

Read more

Ensuring Cup Cleanliness Inspection for Festival Use

November 20th 2024

PEKAT VISION’s AI solution streamlines cup cleanliness inspection for reusable drinkware, detecting defects and contamination, ensuring quality at festivals around Europe.

Read more

Quality Inspection in Pasta Manufacturing

November 14th 2024

Discover how PEKAT VISION's deep-learning software helped a leading pasta manufacturer achieve precise quality inspection, ensuring perfect pasta length with a fast, scalable solution tailored to high-speed production lines.

Read more

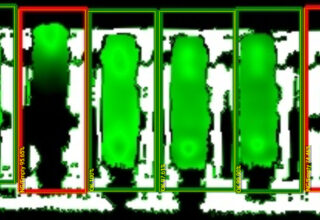

Automating Plant Selection with the Classifier Module

October 31st 2024

Learn how Machine Vision Consulting Srl used PEKAT VISION’s Classifier module to automate plant selection. The system inspects each plant’s health and density, offering consistent quality assessment at scale.

Read more

Deep Learning-based Machine Vision Solution for PCB Recycling

October 15th 2024

Recently we helped Arimation Robotics to develop a deep learning-based solution to rapidly sort over 6,000 PCB bords into 20 categories based on precious metal content, a task that was impossible for human operators due to the sheer volume and complexity.

Read more

The Challenges of Textile Inspection

October 1st 2024

Learn how PEKAT VISION helped a textile manufacturer overcome challenges in detecting defects on large-scale materials using the Anomaly Detection module and custom preprocessing.

Read more

Inspecting the Cleanliness of Plastic Boxes

September 17th 2024

See how PEKAT VISION ensures cleanliness of plastic boxes in the production of plastic toys, identifying and classifying various contaminants and anomalies.

Read more

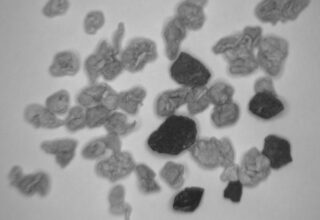

Using NIR Imaging for Food Quality Inspection

August 8th 2024

Explore how NIR illumination enhances contrast between objects and penetrates certain materials, allowing us to 'see through' layers, and proving invaluable in scenarios where traditional lighting methods fall short.

Read more

Machine Vision in Quality Inspection: Traditional vs. Deep Learning Approaches

July 8th 2024

There are two primary approaches to machine vision: traditional (rules-based) and deep learning-based. Understanding their differences, advantages, disadvantages, and specific use cases can help manufacturers choose the most suitable method for their needs.

Read more

PEKAT VISION 3.16 Release

May 13th 2024

Introducing PEKAT VISION 3.16. From enhanced speed to refined user interface, this update represents a culmination of our ongoing efforts to make visual inspection technology more approachable and effective than ever before.

Read more

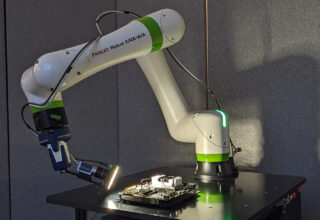

Expanding AI Quality Inspection Options

April 12th 2024

Collaborative robots expand the number of applications suitable for automated quality inspection, they are versatile, easy to set up, repeatable, and affordable. They are particularly helpful in inspecting complex, larger, or heavier product.

Read more

PEKAT VISION Unveils Innovative Smart Camera Solution

March 26th 2024

Introducing the Baumer VAX-50 Smart Camera solution with PEKAT VISION, representing another leap forward in industrial visual inspection, offering superior performance, ease of use, and scalability.

Read more

Datasensing & PEKAT VISION Unveil All-in-One Vision Processor for Industrial Automation

February 13th 2024

Datasensing & PEKAT VISION are proud to announce the release of its innovative Vision Processor, a powerful industrial PC designed specifically to elevate quality control across manufacturing and logistics.

Read more

Ensuring Stress-Free Furniture Assembly: The Role of AI-based Packaging Inspection

October 4th 2023

Have you ever experienced the frustration of assembling furniture, only to discover crucial pieces are missing from the box? The result can be a time-consuming and annoying setback, requiring you to disassemble and head back to the store. Watch a brief demonstration of how our software aids in preventing these assembly hiccups.

Read more

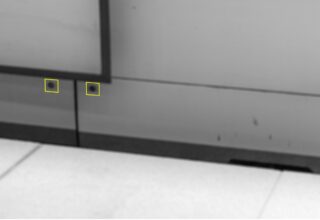

Enhancing Quality Control: How Deep-learning and 3D Imaging Technology Ensure Precision in Fuse Box Assembly

September 14th 2023

Learn how the latest advancements in Photoneo 3D scanning technology and PEKAT VISION deep-learning software has transformed the landscape of quality control in the automotive sector. A single overlooked detail, like an incorrect, or incorrectly seated fuse in a fuse box, can have far-reaching consequences. In our latest blog post we look at how these two companies tackle this challenge head-on.

Read more

Introducing PEKAT VISION Version 3.14

July 11th 2023

We are thrilled to present PEKAT VISION 3.14, the latest version of our cutting-edge visual inspection software, setting a new standard for precision, speed, and accuracy, empowering operators of all technical background to effortlessly train and manage the visual inspection parameters.

Read more

Enhancing Vial Quality Control with PEKAT VISION

June 19th 2023

The advancements in deep learning and computer vision have paved the way for automated inspection in pharmaceutical manufacturing. Inspecting the liquid level of vials is one example of its use. This brief article explores the potential of PEKAT VISION in enhancing vial quality control and highlights the benefits it brings to the pharmaceutical manufacturing process.

Read more

Product Sorting, Defect Detection and Completeness Verification

January 19th 2023

Object Detector and Classifier are two more modules that we would like to briefly describe and provide an example of their use in our blog series. To simulate a real-life scenario, we used different products, a small conveyor belt, and a PLC connected to a signaling beacon. The items, while moving on the conveyor belt, were sorted into the correct product class and inspected for any defect or missing parts. We’re inviting you to look behind the scene at how everything was done.

Read more

A Brief Look at Autumn Trade Fairs. Part II: OCR Module

December 14th 2022

In our next installment of blog series, we will take a look at PEKAT VISION's OCR module used with PhoXi 3D scanner from Photoneo. Using the scanner, we read the embossed characters, including the manufacturer's identification number and DOT number, on the sidewall of a scooter tire.

Read more

A Brief Look at Autumn Trade Fairs. Part I: Surface Detection Module

November 29th 2022

We are introducing a new series of blog posts covering the main modules of PEKAT VISION as they were presented during the autumn trade fairs. In the first part of the series, we will look at the Surface Detection module, used for detecting scratches, cracks, tears in packaging material or shrink wraps, missing parts, burrs on oil seals, or just any kind of surface defect or contamination.

Read more

Completeness Inspection in the Pharmaceutical Industry

August 6th 2022

Searching for defects, either defined, or previously unseen is not the only use of our software. PEKAT VISION can be applied for vision-based robot guidance, product sorting, or completeness check. In this brief article we will look at completeness inspection for the pharma industry.

Read more

Artificial intelligence for plastic inspection – easier than you think!

May 24th 2022

Camera-based inspection systems with artificial intelligence enable product quality control at a level that previously could only be performed by humans. This article explains how and why to use AI in your production and how PEKAT VISION can help you.

Read more

We are proud to announce that PEKAT VISION was acquired by Datalogic for €16 million.

March 22nd 2022

We are proud to announce that yesterday PEKAT VISION was acquired by Datalogic for €16 million.

Read moreGet In Touch

Do you need more information? Let us know, we will answer any question you may have.

PEKAT VISION is now part of Datalogic Group