Die visuelle Inspektions- und Qualitätssicherungssoftware von PEKAT VISION, die auf proprietären Deep-Learning-Algorithmen und neuronalen Netzwerken beruht, ist zu einem unverzichtbaren Werkzeug im Pharmasektor geworden. Sie stellt die Produktqualität sicher, indem sie die Unversehrtheit von Verpackungen und Siegeln überprüft, Sterilität aufrechterhält und eine angemessene Etikettierung sicherstellt, was alles dazu beiträgt, gesetzliche Vorschriften einzuhalten.

PEKAT VISION bietet ein umfassendes Set von Tools, die für verschiedene Herausforderungen in der pharmazeutischen und kosmetischen Produktion entwickelt wurden. Dazu gehören die Überprüfung der Vollständigkeit, die Prüfung der Verpackungsintegrität, die Erkennung von Defekten und Verunreinigungen, das Lesen und Überprüfen von Etiketten und vieles mehr. Im Folgenden finden Sie einige aktuelle Beispiele, die die Fähigkeiten von PEKAT VISION zeigen.

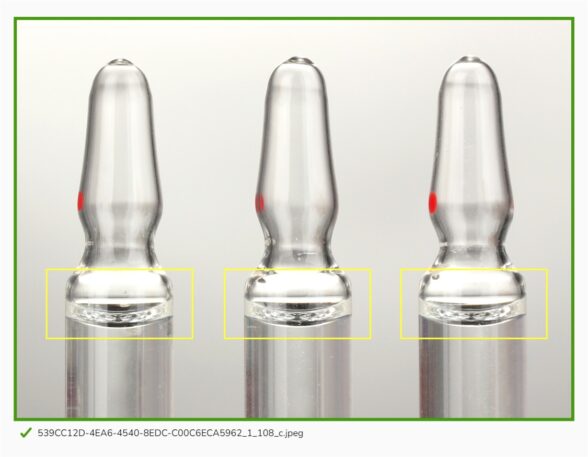

Messung von Flüssigkeitsständen

PEKAT VISION wurde kürzlich zur Messung des Flüssigkeitsstands in Antigentests eingesetzt, um Beschwerden während der COVID-Pandemie über unzureichende oder fehlende Testflüssigkeiten in Ampullen zu begegnen. Diese Technologie prüft auch den Flüssigkeitsgehalt von Fläschchen, Ampullen und Flaschen, oft ergänzt durch Prüfungen der Verpackungsintegrität und der Erkennung von Verunreinigungen. Bei weißen oder bernsteinfarbenen Verpackungen wird häufig Hintergrundbeleuchtung verwendet.

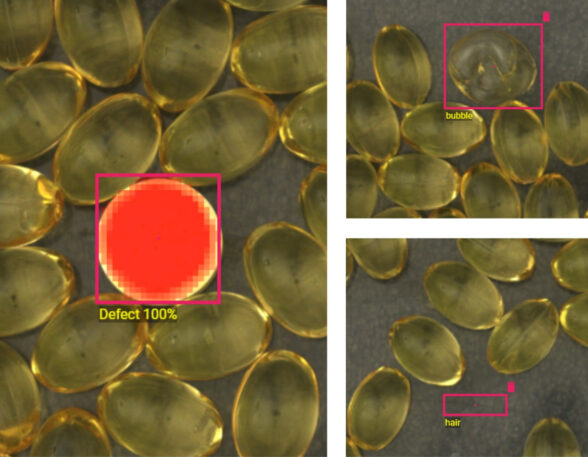

Erkennung von Fremdkörpern

Der Anomalie-Detektor und der Objekt-Detektor von PEKAT VISION werden zur Erkennung von Fremdkörpern in Verpackungen oder Flüssigkeiten eingesetzt. Der Anomalie-Detektor wird nur auf OK-Bilder trainiert und erkennt Abweichungen, wie im linken Bild oben zu sehen ist. Die beiden rechten Bilder zeigen das Modul Objekt-Detektor, das auf die Erkennung bestimmter Objekte trainiert ist.

Hypodermic Needle Sharpness Inspection

Die Schärfe der Nadeln wirkt sich direkt auf den Schmerzpegel während der Injektion aus, was für die Hersteller von Nadeln von entscheidender Bedeutung ist. Das Classifier-Modul von PEKAT VISION bietet eine schnelle und zuverlässige Inspektion, um eine optimale Schärfe sicherzustellen.

Inspektion der Integrität von Tabletten

Die Module Detektor- und Klassifizierung überprüfen, ob die Pillen den erforderlichen Spezifikationen entsprechen, einschließlich Abmessungen, Form, Beschaffenheit und Farbe, und stellen sicher, dass sie frei von Mängeln sind.

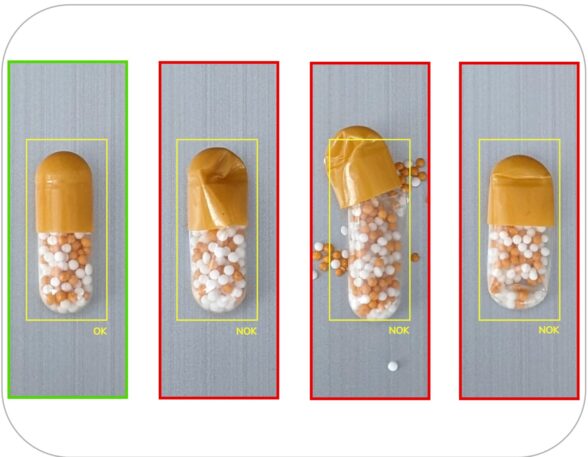

Verpackungsinspektion

Die PEKAT VISION Detektor- und Klassifizierungsmodule sorgen für eine Überprüfung der Vollständigkeit und garantieren, dass nur vollständige Packungen vom Hersteller vertrieben werden.

Inspektion von Tabletten-Blisterpackungen

In der obigen Abbildung überprüfen die Detektor- und Klassifizierungsmodule von PEKAT VISION die Unversehrtheit von Pillen-Blisterverpackungen. Einzelne Mulden und Blister werden erkannt und als OK oder NOK klassifiziert, basierend auf dem Zustand der Pille in jeder einzelnen Tasche.

Inspektion von Flüssigkeitsständen in Fläschchen

Fläschchen sind für die Aufbewahrung von flüssigen Medikamenten von enormer Bedeutung, und der richtige Flüssigkeitsstand gewährleistet eine genaue Dosierung. Das Bild oben zeigt das Classifier-Modul von PEKAT VISION, das den Flüssigkeitsstand in Fläschchen prüft. Erfahren Sie mehr in unserem Blog.

Warum PEKAT VISION

Und noch mehr! Fragen Sie nach einer kostenlosen Machbarkeitsstudie für Ihren speziellen Fall. Unsere Software ist äußerst vielseitig und kann an nahezu jede beabsichtigte Anwendung angepasst werden.