Explore Multi-Module Inspection with PEKAT VISION – Download Our PCB Test Project

Are you curious about how PEKAT VISION can streamline complex visual inspections? We’ve prepared a downloadable dataset and pre-trained project so you can explore its capabilities firsthand.

This example project demonstrates how multiple PEKAT VISION modules—Detector, Unifier, and Classifier—work together to inspect PCB components. By following the guided steps, you’ll see how our AI-driven software:

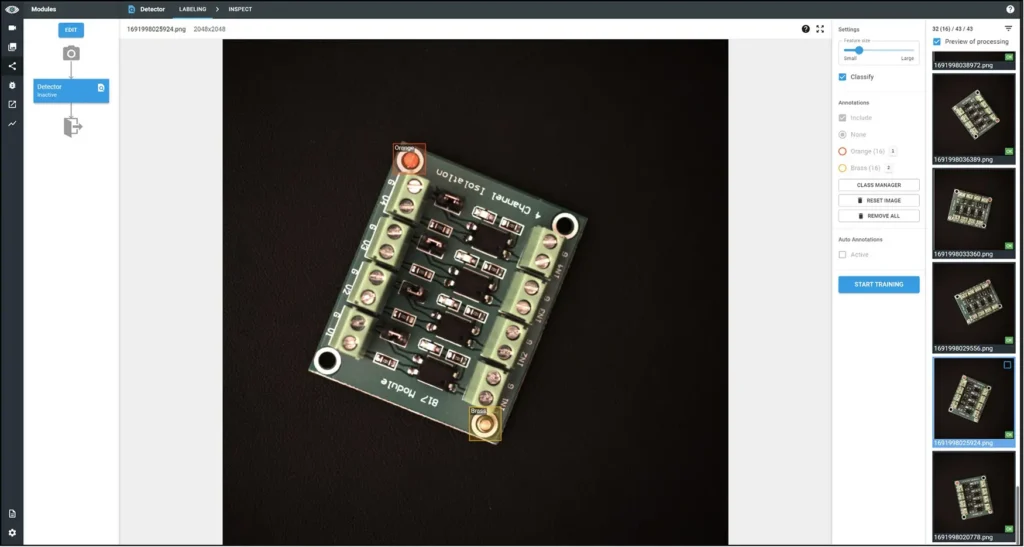

- Detects Reference Points for Alignment

The first step in our example PCB inspection is detecting key reference points for alignment. The Detector module identifies unique elements—orange and brass pins—on each PCB. By training the module to classify these elements, we ensure precise localization, allowing for accurate orientation in the next step.

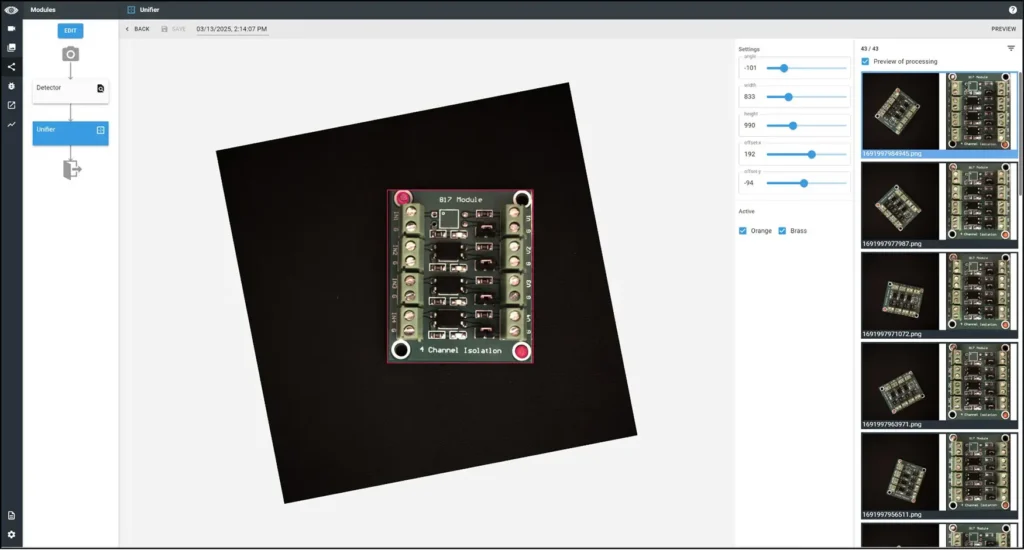

- Aligns and Crops Images for Consistency

PCBs may appear at varying angles due to handling or conveyor positioning. The Unifier module corrects misalignment by rotating and cropping each image based on detected reference points. This ensures that all boards are presented in a standardized orientation, which is crucial for accurate defect detection.

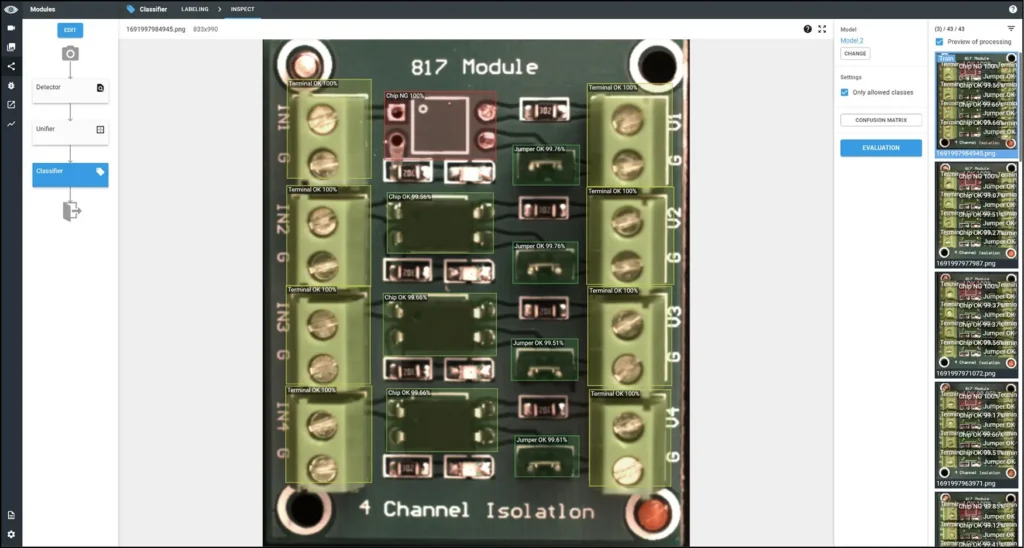

- Classifies PCB Components (OK/NG)

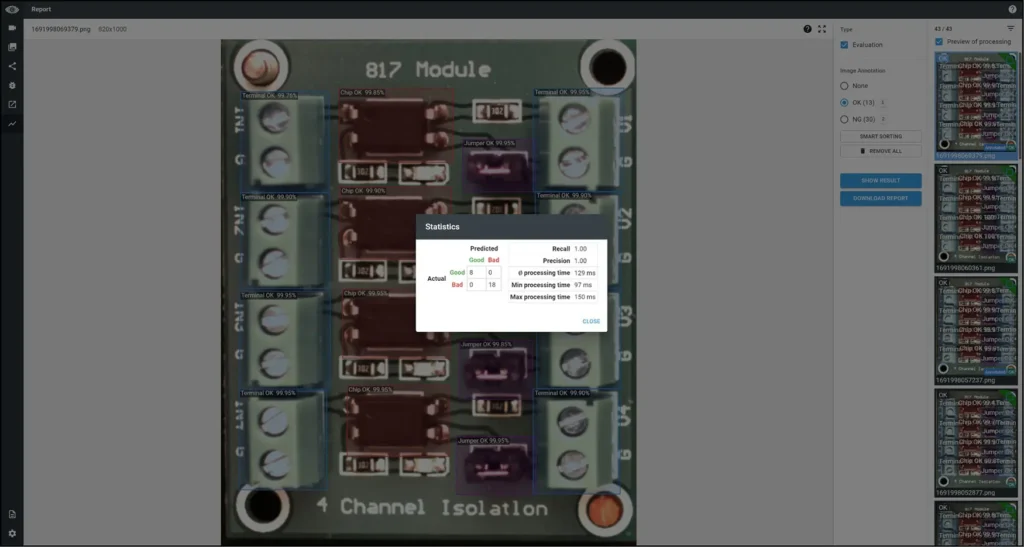

Once aligned, individual PCB components—terminals, chips, and jumpers—undergo inspection using the Classifier module. By training the model on both OK and NG (Not Good) samples, we automatically classify defective parts and determine whether a PCB passes or fails quality checks.

- Automates Pass/Fail Decisions

To define a pass/fail rule, we set conditions based on component classification. If any key component is marked as NG, the entire PCB is flagged as defective. This ensures that only boards meeting strict quality standards proceed further in production.

This test project is designed for demonstration purposes rather than factory deployment. It provides a hands-on way to explore how PEKAT VISION can be used in automated inspections.

Try It Yourself!

Download the dataset, project files, and a step-by-step guide from our Partner Portal to explore PEKAT VISION’s capabilities. If you already have a customer account, no need to register again—simply log in with your existing credentials and navigate to Datasets to get started.

Not yet registered? Sign up here and request access to the Partner Portal.