Nowadays, the visual inspection of transparent materials is still a challenge in machine vision projects. Our latest case study is focusing on this specific issue. In cooperation with ATEsystem s.r.o. we have performed a feasibility study for glass inspection and we are glad to share these results with you.

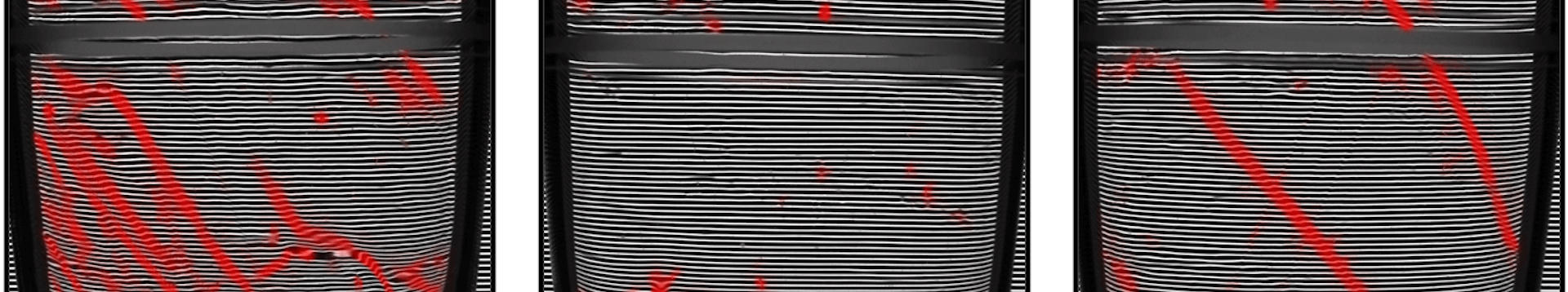

The main issue when performing glass inspection, is the fact that defects are very hard to be detected even for the human eye. In order to make the defects more visible, we used a pattern light lines – type CCS LFX3-PT Series. Using this approach, we are able to see various types of defects on glass materials.

Our software is able to detect the following type of defects: material inhomogeneity, cracks, battered glass, general glass defects or foreign objects encapsulated in the glass.

We used a Basler monochrome camera for image acquisition. PEKAT VISION software contains drivers for Basler cameras, therefore the USB camera can be connected directly to the application.

Lastly, we uploaded images to PEKAT VISION and started training using our Surface Detection AI module, which successfully recognised all expected defects. The processing time for each image was on average 40 ms (resolution 1024 x 784, GPU 1080Ti).

If you want to know how PEKAT VISION would deal with defects you want to eliminate, we offer the possibility of conducting a Feasibility Study – you can contact us directly through this link https://pekatvision.atlassian.net/servicedesk/customer/portal/4/group/5/create/28

or through our website: https://www.pekatvision.com/contact.

Find more detailed explanations on our YouTube channel https://www.youtube.com/channel/UCvbx26TqHNgbIVAY-80XJ1A.

We would like to thank ATEsystem s.r.o. for providing the camera components.