As we embark on a new year, we are excited to share a new use case that demonstrates how PEKAT VISION contributes to patient well-being. This time, our focus is on the inspection of catheter packaging to ensure only complete and properly sealed packages reach hospitals. Catheters, essential in medical care, are used to drain fluids, deliver medications, or aid in diagnostics. Given their critical role, it is imperative that the packaging is both intact and complete to safeguard the health and safety of patients.

The Challenge of Catheter Packaging Inspection

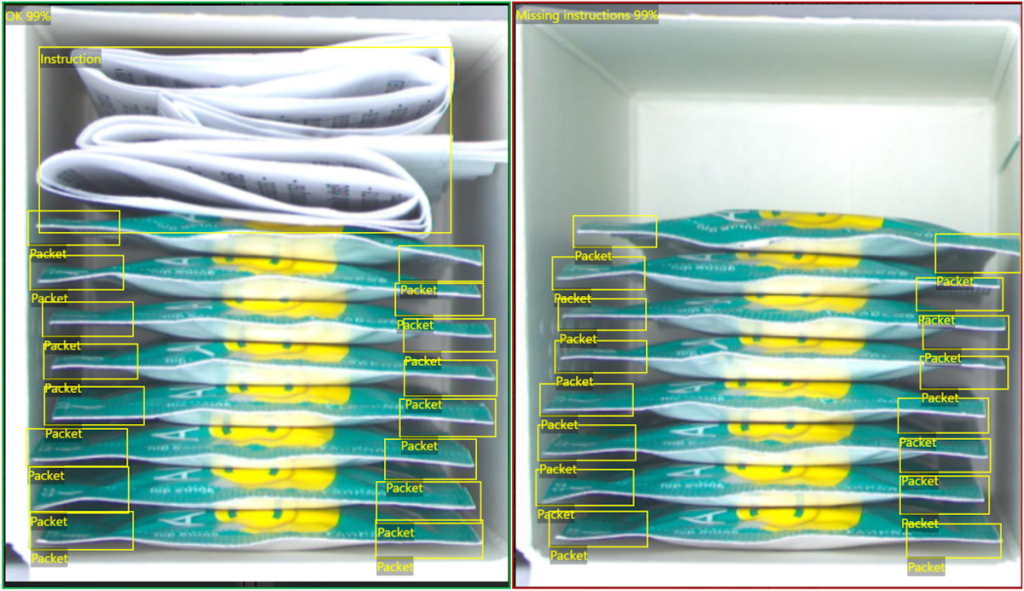

The task was to inspect transparent, branded catheter packaging consisting of multiple individual pockets. Each pocket contained a complete catheter, which included components such as a translucent tube and a cap. These pockets were designed to hold catheters that could easily be separated. We needed to ensure that each pocket contained a complete catheter in the correct position, that all pockets were properly sealed, and that no parts were obstructing the seal. Additionally, missing or misplaced components needed to be identified accurately, even with the challenge of translucent materials.

The Solution: Advanced Inspection Techniques

We approached the inspection by dividing the task into two parts:

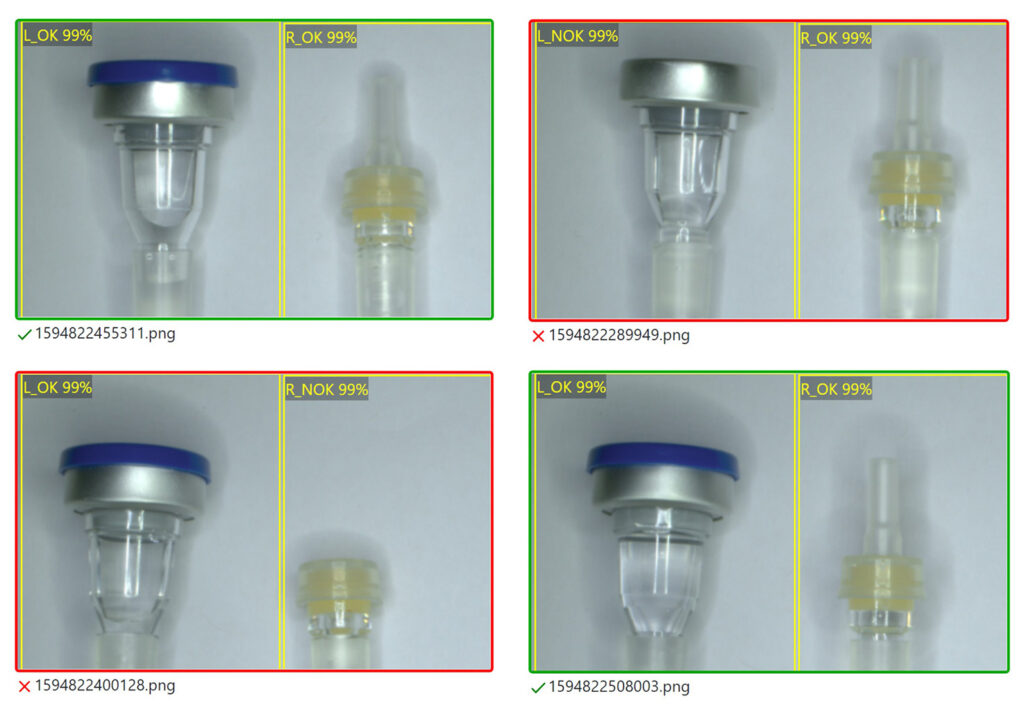

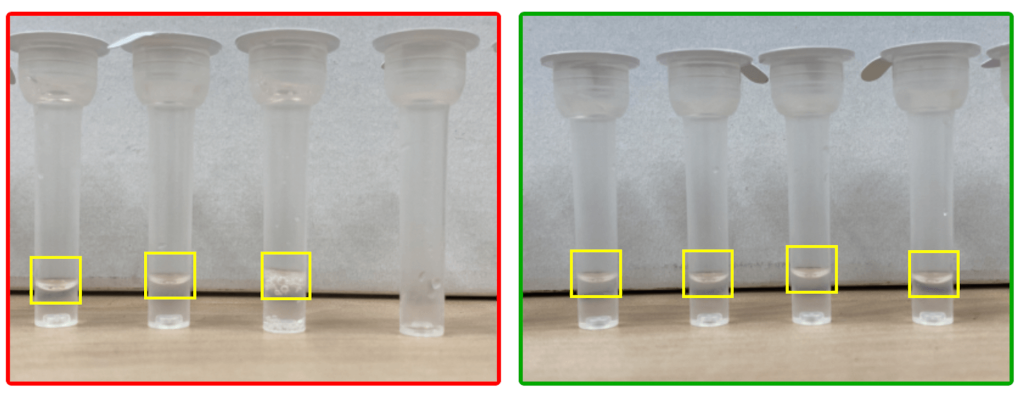

- Whole Image Packaging Inspection Using a backlight, we scanned the entire packaging to confirm the presence of translucent catheter tubes in each pocket. This method also enabled us to detect anomalies, such as missing or misplaced components. The PEKAT VISION Detector and Classifier modules were essential in ensuring accurate identification during this stage.

- Detailed Component and Seal Inspection In the second stage, we verified the presence, correct position, and orientation of all components—tubes, caps, and other elements—within each pocket. Simultaneously, we inspected the sealing of the pockets to confirm proper closure and ensure that no parts obstructed the seal. This comprehensive inspection was achieved by utilizing the PEKAT VISION Detector along with a simple code evaluation to validate completeness and seal integrity for each pocket.

The Outcome of the Inspection

This two-step inspection process ensures a high level of accuracy in detecting incomplete or improperly sealed catheter packages. By leveraging the advanced capabilities of PEKAT VISION, manufacturers can confidently deliver catheter packaging that meets the highest standards of quality and safety, directly contributing to the well-being of patients worldwide.

Our solution doesn’t stop here. We offer a free feasibility study to help you determine not only whether your project is feasible but also the best possible way to address your specific challenges. Send us your use case, and let us help you solve it with precision and efficiency.

Our expertise spans beyond catheter inspection. We have successfully tackled various use cases in the pharmaceutical industry, including completeness inspection of medication packaging, detecting defective pills, vial quality inspection, and fluid level detection in antigen test tubes. With PEKAT VISION, you can ensure the highest standards of quality in your production process.

Let’s start the year by solving your most challenging quality inspection tasks together!