With the festive season fast approaching, what better way to celebrate than with a Christmas-themed use case? This time, we explore quality inspection of Christmas chocolate boxes—specifically focusing on completeness inspection. In the process, we’ll highlight two PEKAT VISION modules, each uniquely suited to different tasks.

Anomaly Detection for Completeness Inspection

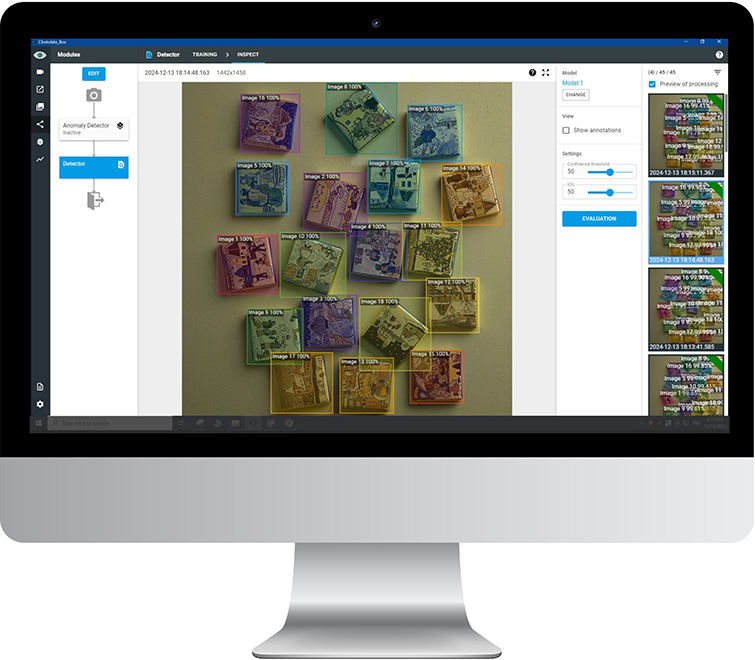

For inspecting the overall state of the box, we first used the Anomaly Detector module. This module is quick to set up and requires minimal effort for training. Using just a few images of correctly packed boxes, we uploaded them to PEKAT VISION, selected the module, and initiated training. Well before our colleague Pepe, the office’s coffee aficionado, finished brewing a cup of coffee, the training was done.

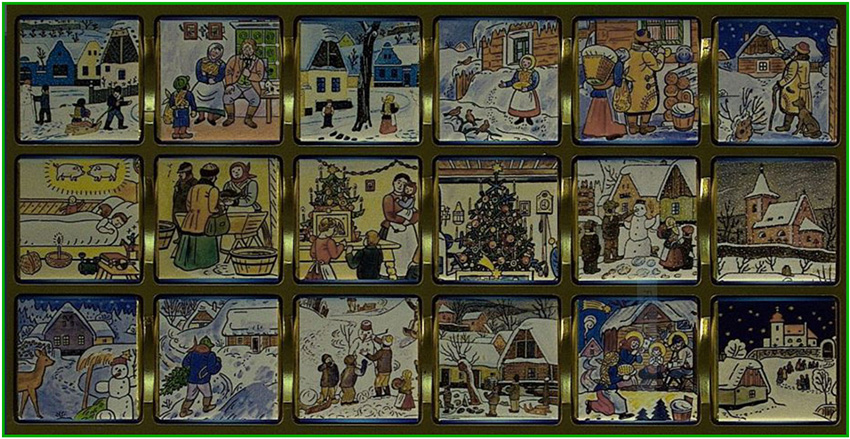

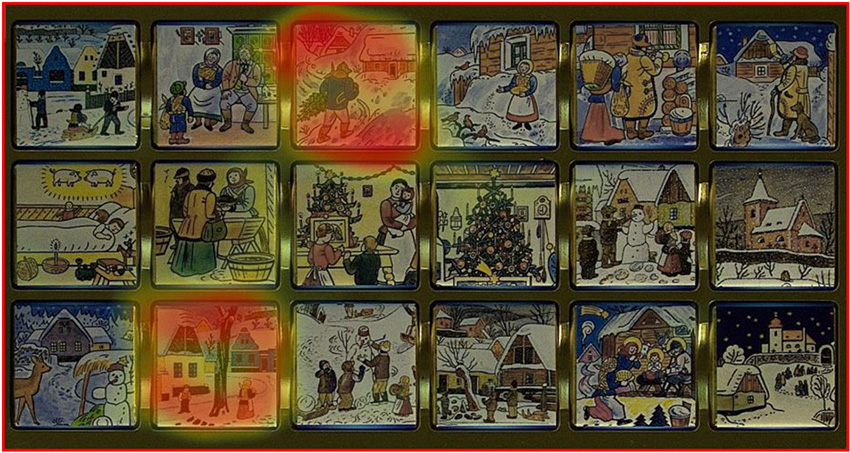

When tested, the Anomaly Detector successfully identified incomplete boxes and detected chocolates that were in the wrong positions (Images 2 and 3).

Super quick and easy to set up, the Anomaly Detector’s additional benefit is its versatility—it not only inspects the contents of the chocolate box but also flags any other defects, whether inside or outside the box, that deviate from the norm. Its simplicity and speed make it an ideal choice for many applications.

But let’s explore a completely different approach, offering its own unique advantages:

Detector & Classifier Module for Precise Quality Inspection

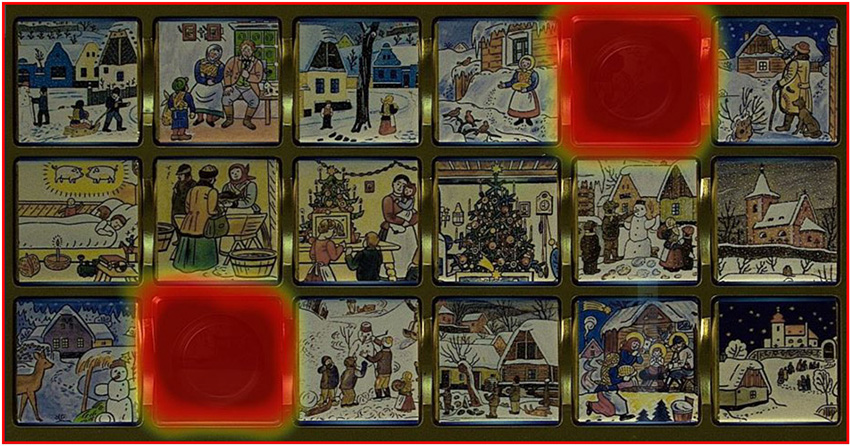

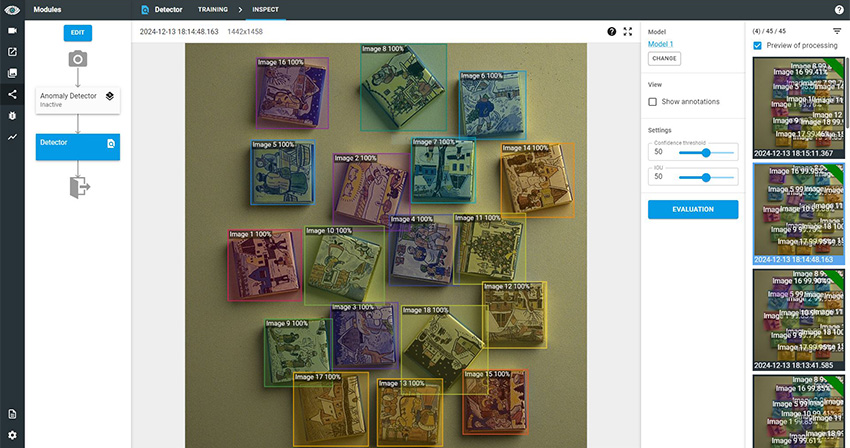

The Detector & Classifier module focuses on identifying and classifying specific objects or defects. For our scenario, we annotated each chocolate and assigned it a unique class (1–18), along with a separate class for an empty position.

If the goal were only to identify incomplete boxes, we could simply train the module using a few images containing “Empty” classes. The module would then flag any box with one or more missing chocolates.

However, we went a step further by classifying each type of chocolate individually. This allowed us to inspect scenarios where every box must contain exactly one of each chocolate type. We set evaluation criteria to detect not only incomplete boxes but also those with duplicates of the same chocolate. It’s a colorful, festive solution that matches the holiday spirit while delivering precise quality control (Images 4 and 5 below).

This module’s flexibility makes it perfect for handling complex tasks where classification of individual items is essential.

Identifying Scattered Chocolates

What if the chocolates aren’t neatly packed but scattered randomly—for example, on a conveyor belt before boxing? Once again, the Detector & Classifier module excels here. Regardless of the chocolates’ positions or orientations on the conveyor, it accurately identifies each piece (Image 6). This makes it ideal for tasks where precision and adaptability are crucial.

Finding the Best Module for Your Needs

Not sure which PEKAT VISION module is best for your quality inspection challenges? We offer a free feasibility study, where our team of experts evaluates your application and recommends the optimal solution.

For more examples, check out how the Anomaly Detector module excels in inspecting continuous materials or detecting contaminants in meat production. Or explore how the Detector & Classifier module is used for safety inspections of railway carriages, cleanliness checks of reusable plastic cups, and quality control in pasta manufacturing.

From all of us at PEKAT VISION, we wish you a Merry Christmas and a Happy, defect-free New Year (professional habit, sorry!).