IA based visual inspection has become a vital part of the vehicle manufacturing process. What gave car manufacturers a competitive edge a couple of years ago has now become a necessary part of the manufacturing process. PEKAT VISION has been working closely with leading manufacturers from the start.

From pre-shipment inspection by automotive parts suppliers, or pre-assembly inspection at an assembly plant preventing costly rework further up the manufacturing process, up to the final inspection before a vehicle is shipped to the showroom, PEKAT VISION helps cut waste, improve product quality, increase productivity, and meet stringent vehicle safety standards.

Virtually any car part requiring visual inspection, including defect detection, completeness check, product sorting, OCR or character verification can be completed by PEKAT VISON.

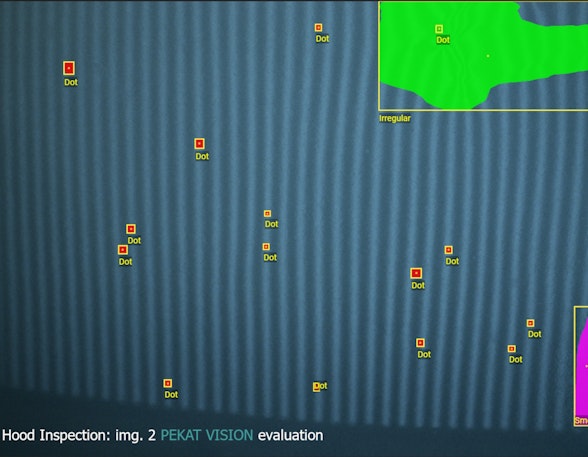

Inspection of Body Panels

PEKAT VISION is able to find cosmetic flaws, including dents, dings, wrinkles, varnish defects, or scratches on a variety of body panels. Line patterns can be projected over the surface to make defects easier to identify as in the case above. Using an area scan camera and the Surface Detector module, these defects are easily identified

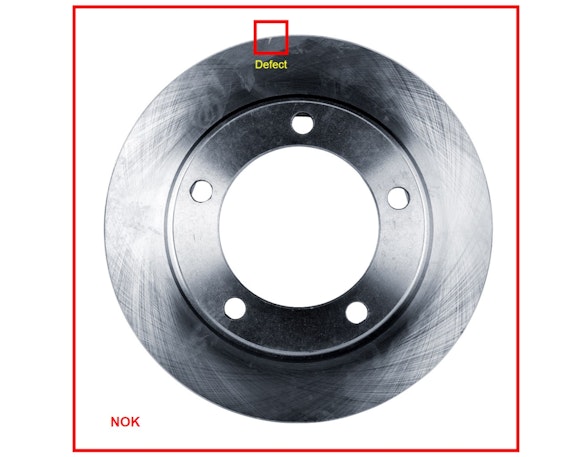

Powertrain and Chassis

PEKAT VISION enables visual inspection of powertrain and chassis components, including those critical for vehicle safety such as brake discs. It efficiently detects cracks and other potentially hazardous defects of the disc that could lead to a safety hazard, excessive heating of the brake, increase noise levels or increased wear and tear

Inspection of Interior Parts

Car interior parts including plastic linings, seat upholstery, or other small parts of the interior can be inspected for defects and assembly verification with multiple PEKAT VISION modules

Other Miscellaneous Car Parts

Cosmetic as well as functional defects in a variety of other car components are easily detected with PEKAT VISION. A small scratch and a faulty part are identified on a car key using the Detector module

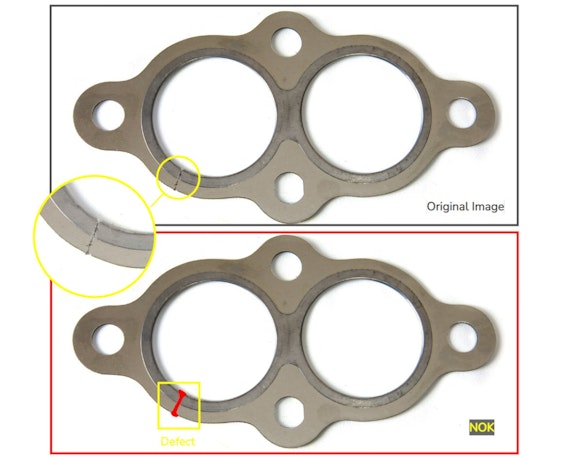

Pre-Assembly Inspection of Components

Inspecting the components before they are assembled can reduce costly rework. Multiple PEKAT VISION modules are suitable for this task. Pictured above is the result of the Surface Detector module

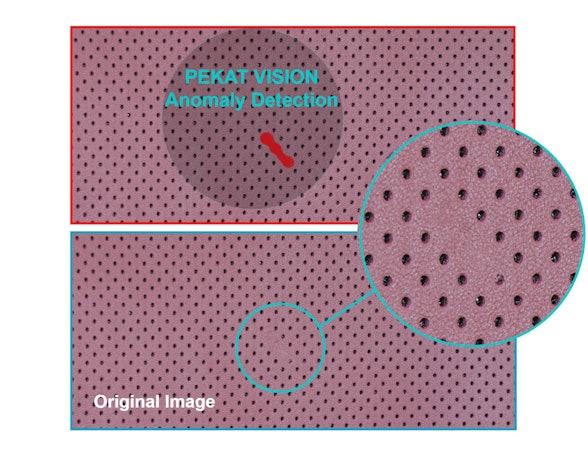

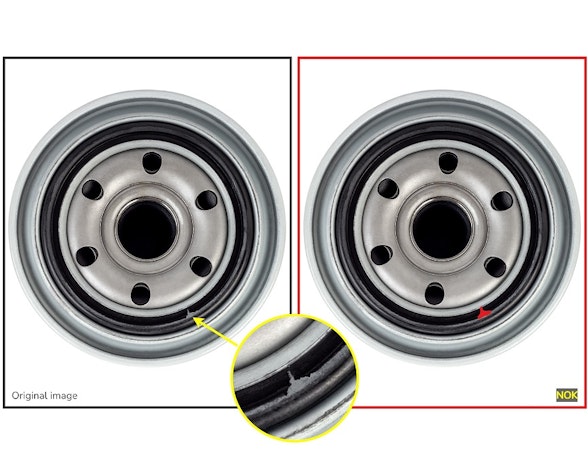

Oil Filter Seal Inspection

The seal on oil filters is inspectded with the Anomaly Detector modul to identify possible defect or missing seal preventing oil leakages on assembled vehicles. Only Defect free images are necessary for the training of the module

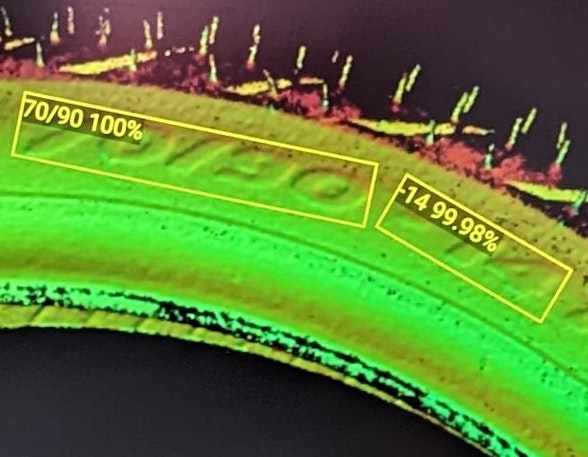

OCR/ OCV

Deep-learning OCR (Optical Character Recognition) and OCV (Optical Character Verification) modules read stamped part numbers, serial numbers, manufacturer identification numbers, or batch information, for example, and are used for parts tracking and during assembly verification

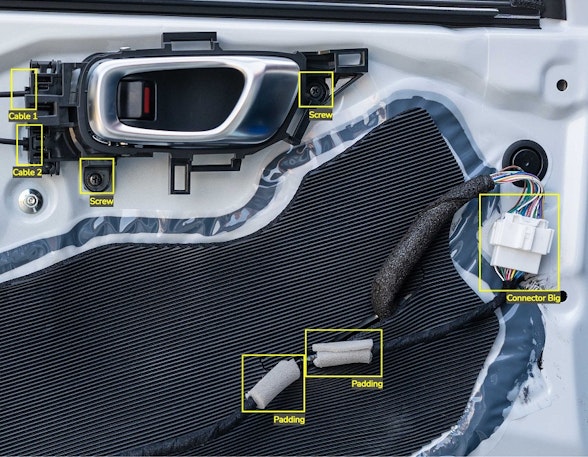

Pre-Assembly Verification

During the car door unit assembly, component presence is verified using the PEKAT VISION Detector module. The module is trained on images where components are present – OK – as well as where components are missing – NOK

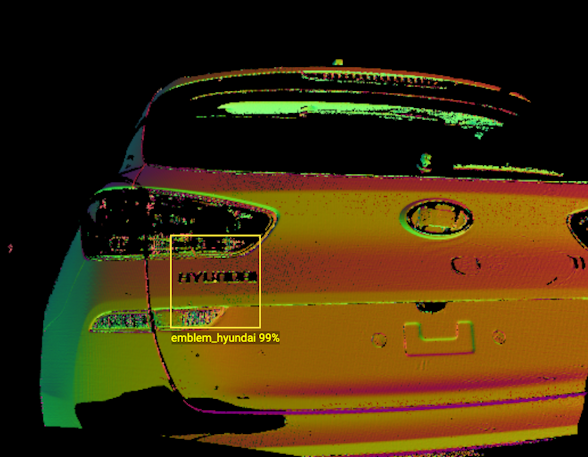

Final Assembly Verification

The final stage assembly verification ensures that all components such as mirrors, lights, door handles, and emblems, are properly assembled. 3D scanners can be used with PEKAT VISION

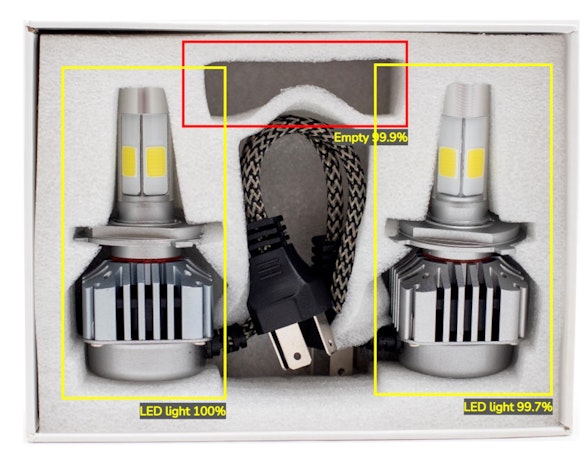

Spare Parts Completness Inspection

Components presence/ absence is vital not only for component manufacturers. PEKAT VISION helps ensure that packaging, or any vehicle part, contains all its components

And more! Ask for a free feasibility study for your specific case. Our software is highly versatile and can be customized to suit nearly any intended application.