Recently, we were approached by a client with a unique challenge: inspecting locks and latches on railway carriages using AI as a part of their safety inspection carried out while the train is in the depot.

The carriages would move slowly through a depot while stationary cameras captured continuous images. Since some locks were positioned on the roof and others near the base of the train, multiple cameras had to be strategically placed at various heights and distances from the carriages. The identification numbers of the carriages would be registered, and each lock and latch would be numbered for easy identification of any that were left open. But that’s a story for another time.

The Task for PEKAT VISION

Our focus was on image analysis. The objective was straightforward. We were to identify whether the relevant locks and latches were open or closed.

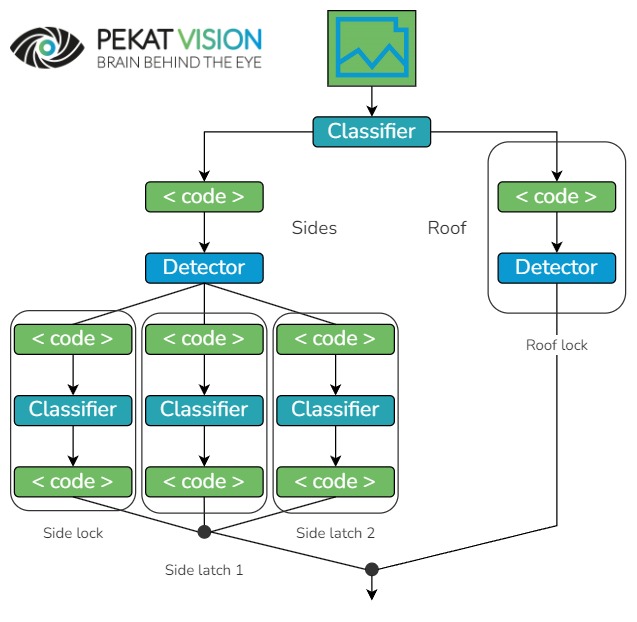

The first challenge: The images from different parts of the carriages were mixed together. Fortunately, this wasn’t an issue. We employed the PEKAT VISION Classifier, combined with a simple if-else conditional code, to sort the images into two main branches: “Roof” and “Sides”.

If an image of the roof was identified, the code sent the image to the ‘Roof’ branch. If the image was from the sides of the carriage, it was sent to the ‘Sides’ branch, which was further subdivided based on the lock or latch identified using another set of conditional logic.

Once the images were sorted into their respective branches, the Detector with Classifier module determined whether the lock or latch was in a locked or open state.

Potential obstacles such as dirt, grease, graffiti, rust or varying camera angles had no negative impact on the accuracy of the results. PEKAT VISION managed to handle these conditions flawlessly.

All defects were detected. But we went beyond…

Everything seemed to be working perfectly until our feasibility team noticed something during testing. In a few cases, although the latches were properly closed, the covers they were supposed to secure at its place were missing.

This revealed that the inspection needed to focus not only on the state of the latches and locks but also on the presence or absence of covers. Fortunately, this wasn’t a major setback. Identifying this gap during the feasibility study phase was exactly the kind of insight we aim to provide.

Wondering if we can solve your inspection challenges? Whether it’s a quality issue on a production line or a safety concern on something as large as a train, send us your images for a free feasibility study. Let PEKAT VISION help you achieve reliable results.