基于深度学习的视觉检测技术可显著提升食品与饮料行业的产品质量与安全性,有效防止高成本的召回事件,同时显著提升生产效率。传统检测方式(如人工检测)存在耗时长、主观性强、易出错等缺陷,易导致产品质量参差不齐,甚至存在安全隐患的产品流入市场。

PEKAT VISION 采用专有深度学习算法与神经网络架构,可实时精准分析海量视觉数据,有效识别传统方法可能遗漏的缺陷与异常。其功能模块可涵盖检测:固体异物识别、包装完整性验证、标签合规性检查、保质期信息读取等。

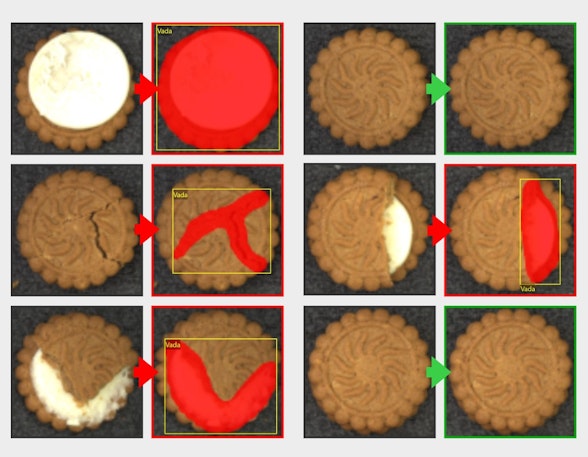

产品质量和一致性检测

在饼干等精致食品生产过程中,深度学习视觉检测系统可实时识别产品缺陷,确保成品外观与规格的高度一致性。

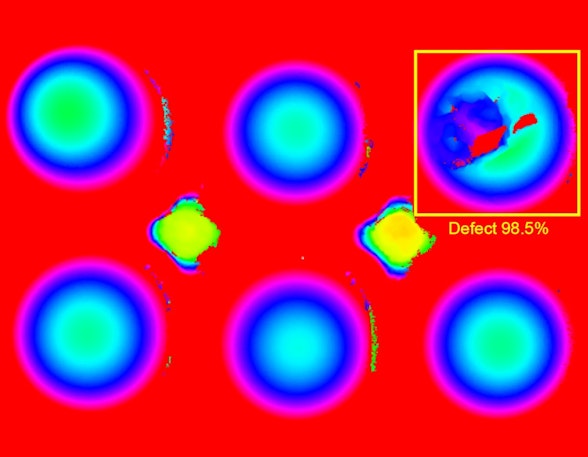

3D 缺陷和破损检测

针对传统2D视觉系统难以有效检测的产品,3D视觉检测技术可实现立体缺陷的精准识别。

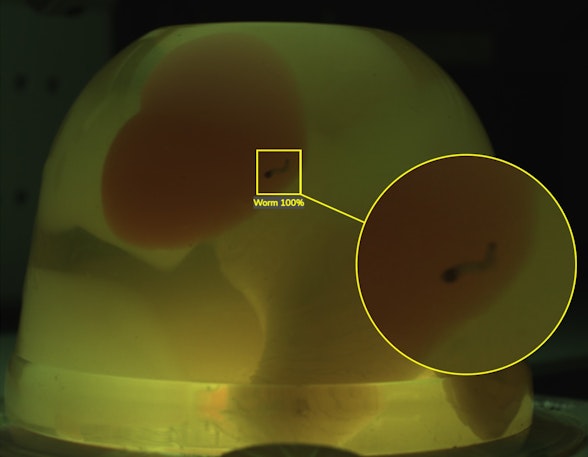

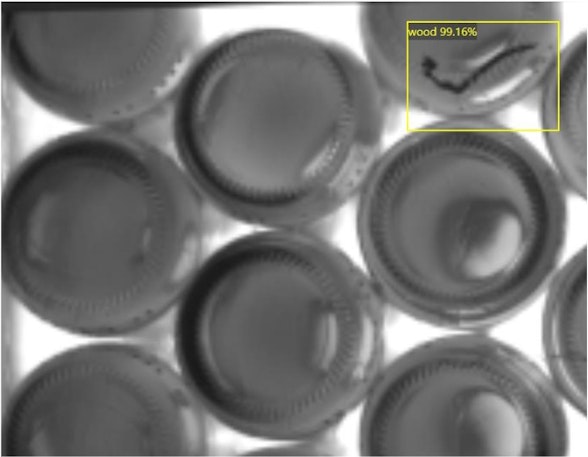

污染检测

通过早期识别包装食品中的污染物,可显著提升产品安全性,减少物料浪费,并降低品牌声誉受损及产品召回风险。

OCR/OCV 检测

基于深度学习的光学字符识别(OCR)模块与光学字符验证(OCV)模块协同工作,用于识别过期产品、实现产品分类及食品溯源。

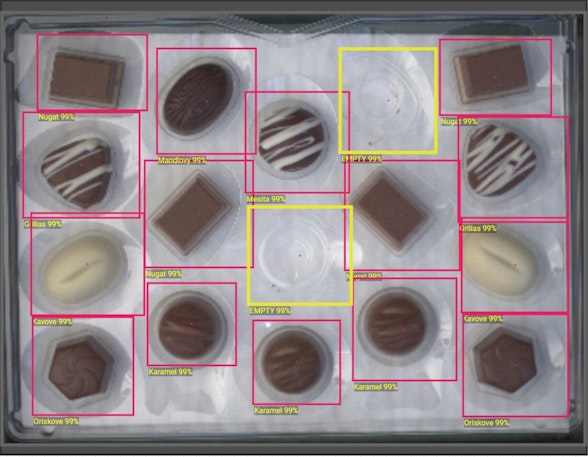

包装内容检测

如检测示意图所示,PEKAT VISION 的检测与分类模块通过识别包装内物品,验证组件完整性,确保所有物品正确装配且无损坏。

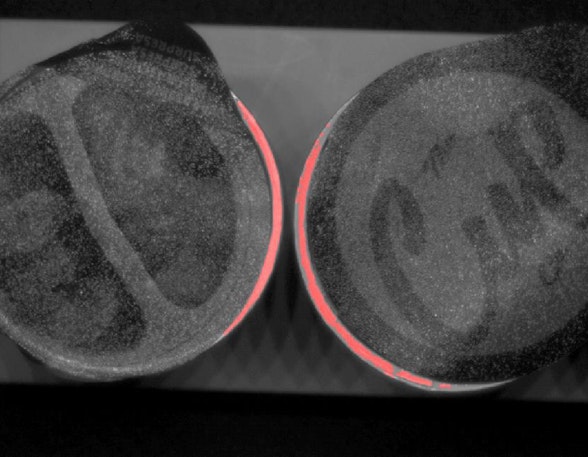

包装检查

异常检测模块可识别各类产品异常,如咖啡胶囊检测场景中,铝箔密封未完全覆盖边缘区域的问题,避免内容物泄漏风险。

包装洁净度检测

如检测示意图所示,空瓶在灌装前需经过污染检测,确保容器洁净度符合标准。

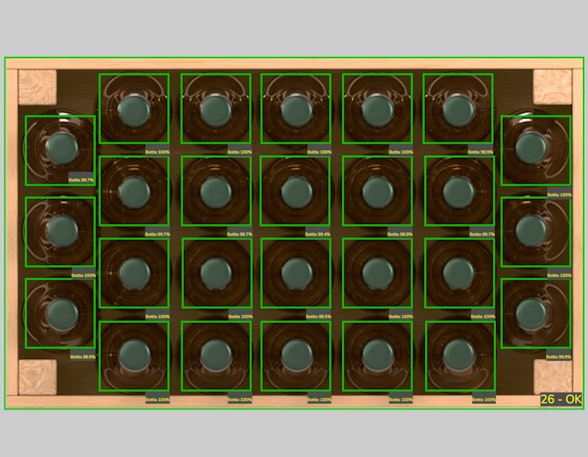

最终包装检查

在木箱葡萄酒密封发货前,PEKAT VISION对瓶体及包装进行最终检测与数量核对,避免破损产品或包装不全的产品送达客户。

为何选择 PEKAT VISION

易用性与兼容性

PEKAT VISION 提供直观且用户友好的软件环境。软件已内置工业视觉检测所需的全套模块,用户无需编程知识即可操作。系统兼容多个硬件品牌,支持 Windows® 和 Linux® 操作系统,并可在嵌入式设备上运行。

快速集成

通过预定义输出规则可显著加快集成进程。此外,我们与全球合作伙伴保持紧密协作,可根据具体业务需求协助硬件选型,确保系统在企业环境中平稳集成。

全面支持

为提供最优解决方案,我们始终优先理解客户的具体需求,确保解决方案与客户需求精准匹配。服务包含免费可行性研究、30天免费试用、实施全程及后续支持,以及全面的操作培训。

还有更多功能!欢迎就您的具体案例咨询免费可行性研究。本软件具有高度通用性,可根据各类应用场景进行定制化解决方案适配。

PEKAT VISION is now part of Datalogic Group