Automating PCB Inspection

April 16th 2025

Our example project demonstrates how multiple PEKAT VISION modules—Detector, Unifier, and Classifier—work together to inspect PCB components.

阅读更多

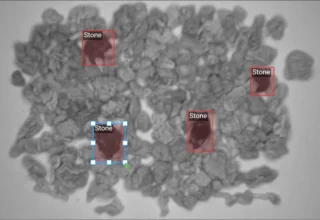

Detecting Food Contaminants with the Detector Module

April 3rd 2025

Take a closer look at how does the detector module work in food inspection. Now, you can try it yourself—or just read along.

阅读更多

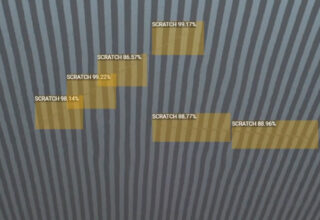

Defect Detection on Reflective Surfaces

February 21st 2025

Patterned illumination significantly enhances defect detection on glossy and reflective surfaces. Combined with PEKAT VISION's deep learning software, it provides a reliable, automated quality control solution for challenging inspection tasks.

阅读更多

PEKAT VISION RELEASE 3.18: What’s New?

January 17th 2025

The latest release of PEKAT VISION, version 3.18, brings exciting new features and improvements designed to enhance performance, usability, and flexibility for your quality inspection projects.

阅读更多

Ensuring Patient Safety with Reliable Catheter Packaging Inspection

January 9th 2025

Discover how PEKAT VISION detects incomplete or improperly sealed catheter packages to meet the highest quality standards.

阅读更多

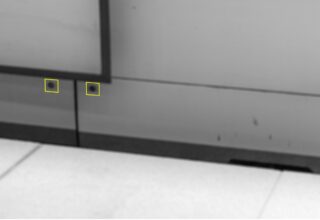

AI-Powered Safety Inspection for Railway Carriages

December 13th 2024

Deep learning for railway safety inspections? We recently tackled an unconventional use case—automating the inspection of locks and latches on slowly moving railway carriages!

阅读更多

Final Packaging Inspection in Meat Production

December 5th 2024

Explore how PEKAT VISION's Anomaly Detector streamlines packaging inspection in meat production, detecting foreign contaminants like foil or paper and ensuring the highest quality before sealing. Learn more about its speed, accuracy, and flexibility for food inspection.

阅读更多

Ensuring Cup Cleanliness Inspection for Festival Use

November 20th 2024

PEKAT VISION’s AI solution streamlines cup cleanliness inspection for reusable drinkware, detecting defects and contamination, ensuring quality at festivals around Europe.

阅读更多

Quality Inspection in Pasta Manufacturing

November 14th 2024

Discover how PEKAT VISION's deep-learning software helped a leading pasta manufacturer achieve precise quality inspection, ensuring perfect pasta length with a fast, scalable solution tailored to high-speed production lines.

阅读更多

Automating Plant Selection with the Classifier Module

October 31st 2024

Learn how Machine Vision Consulting Srl used PEKAT VISION’s Classifier module to automate plant selection. The system inspects each plant’s health and density, offering consistent quality assessment at scale.

阅读更多

Deep Learning-based Machine Vision Solution for PCB Recycling

October 15th 2024

Recently we helped Arimation Robotics to develop a deep learning-based solution to rapidly sort over 6,000 PCB bords into 20 categories based on precious metal content, a task that was impossible for human operators due to the sheer volume and complexity.

阅读更多

The Challenges of Textile Inspection

October 1st 2024

Learn how PEKAT VISION helped a textile manufacturer overcome challenges in detecting defects on large-scale materials using the Anomaly Detection module and custom preprocessing.

阅读更多

Inspecting the Cleanliness of Plastic Boxes

September 17th 2024

See how PEKAT VISION ensures cleanliness of plastic boxes in the production of plastic toys, identifying and classifying various contaminants and anomalies.

阅读更多

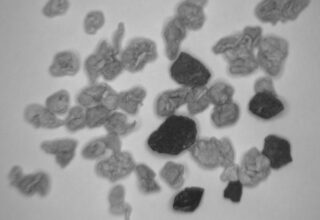

Using NIR Imaging for Food Quality Inspection

August 8th 2024

Explore how NIR illumination enhances contrast between objects and penetrates certain materials, allowing us to 'see through' layers, and proving invaluable in scenarios where traditional lighting methods fall short.

阅读更多

Machine Vision in Quality Inspection: Traditional vs. Deep Learning Approaches

July 8th 2024

There are two primary approaches to machine vision: traditional (rules-based) and deep learning-based. Understanding their differences, advantages, disadvantages, and specific use cases can help manufacturers choose the most suitable method for their needs.

阅读更多

PEKAT VISION 3.16 Release

May 13th 2024

Introducing PEKAT VISION 3.16. From enhanced speed to refined user interface, this update represents a culmination of our ongoing efforts to make visual inspection technology more approachable and effective than ever before.

阅读更多

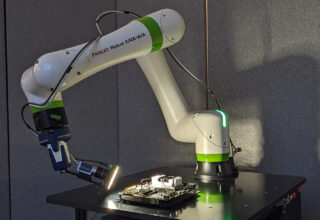

Expanding AI Quality Inspection Options

April 12th 2024

Collaborative robots expand the number of applications suitable for automated quality inspection, they are versatile, easy to set up, repeatable, and affordable. They are particularly helpful in inspecting complex, larger, or heavier product.

阅读更多

PEKAT VISION Unveils Innovative Smart Camera Solution

March 26th 2024

Introducing the Baumer VAX-50 Smart Camera solution with PEKAT VISION, representing another leap forward in industrial visual inspection, offering superior performance, ease of use, and scalability.

阅读更多

Datasensing & PEKAT VISION Unveil All-in-One Vision Processor for Industrial Automation

February 13th 2024

Datasensing & PEKAT VISION are proud to announce the release of its innovative Vision Processor, a powerful industrial PC designed specifically to elevate quality control across manufacturing and logistics.

阅读更多PEKAT VISION is now part of Datalogic Group