The manufacturers of braided cables need their products to be very flexible and remain in perfect condition for a long period of time. To achieve that, the customer needs to achieve 100% flawless product. PEKAT VISION software is an effective, fast and easy way to achieve that as you can see in our new case study.

This time we detect defects on the braided cable using our Anomaly of Surface module, which is perfect for a scenario when defects you are looking for are not predictable.

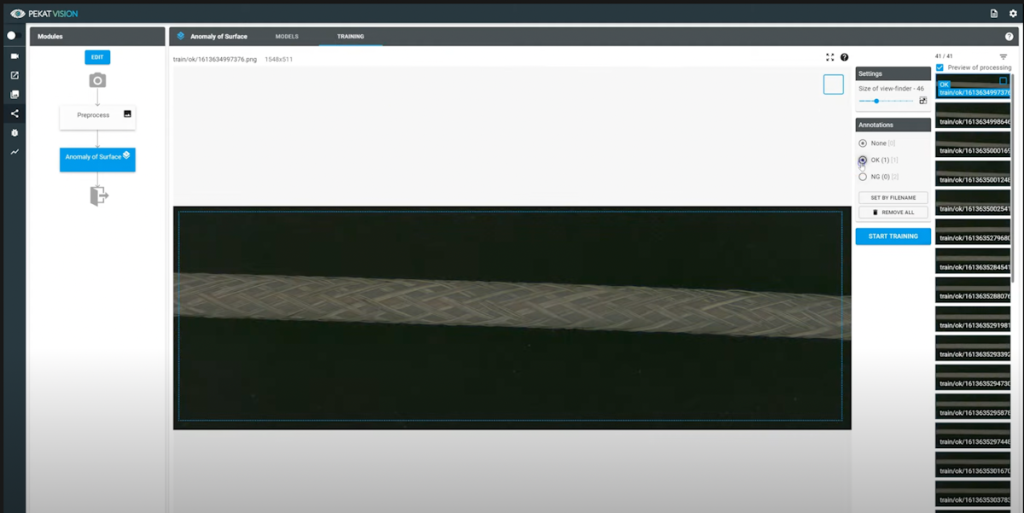

The way the Anomaly of Surface module works is very simple. It uses only defect free pictures for training. Firstly, you need to assign at least 10 images as good, and then you can start training.

After training is completed, you select “Calculate Sensitivity”. In that case, you assign all images as OK and NG (not good), and the software will automatically calculate and set a recommended sensitivity value. However, if you are not completely satisfied with the detection accuracy, you can adjust the detection sensitivity, in order to increase or decrease precision.

In the picture you can see the graph that shows other values for “automatic sensitivity” function. According to this graph you can find out which sensitivity is optimal for 100% accurate evaluation.

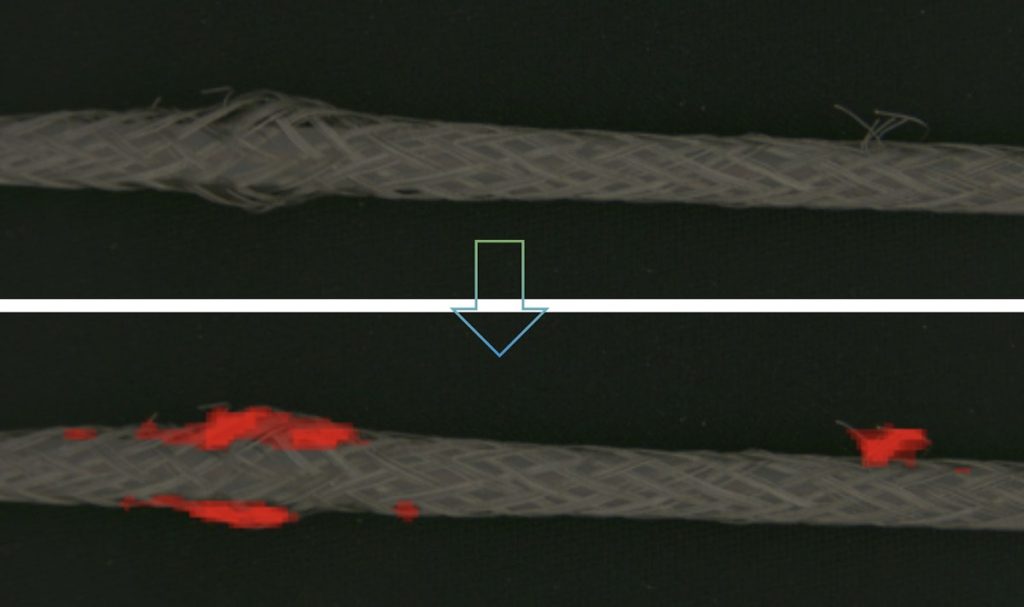

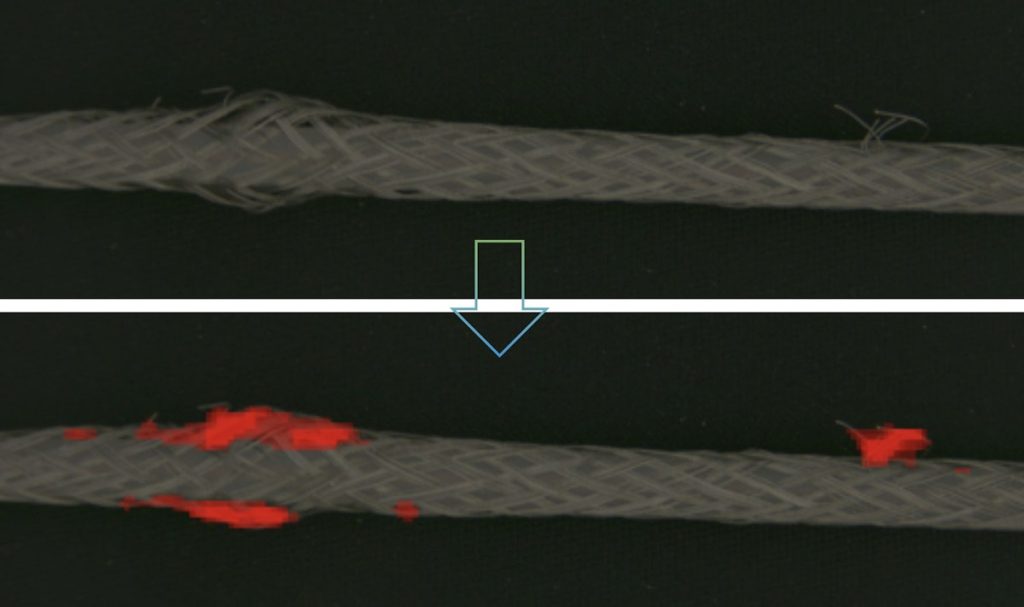

You can check the results on all uploaded images – a heatmap will show the exact area where the defect was detected.

If you would like to see step-by-step, we have recorded a new tutorial video for braided cables, using Anomaly of Surface module: